Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Comparison Analysis on Technology and Economics in Reinforcement Methods in Frame Column

The installed capacity of a power plant is a 2 x 660MW domestic coal-fired supercritical power generation unit, and the No. 1 main building has a bent-frame structure. The main factory building A is a bent frame structure. The concrete strength grade design requirements of No. 1 main powerhouse are: the concrete strength grade of frame columns and longitudinal beams below 14.7m is C50, and the above concrete strength grade is C40. The frame level is level 1, and the shear wall level is level two. Due to poor quality control during construction, material fluctuations and construction mix ratios, the strength of frame columns below 14.75m in the main factory building cannot meet the design requirements. Appraisal by a qualified inspection unit, the strength value of this part is 36.1-42.3MPa, and the safety level of frame columns and beams is rated as C level. In order to ensure that the structure meets the requirements for use and durability, it is necessary to check and reinforce the concrete columns below 14.65m below C50.

Enlarged section reinforcement method

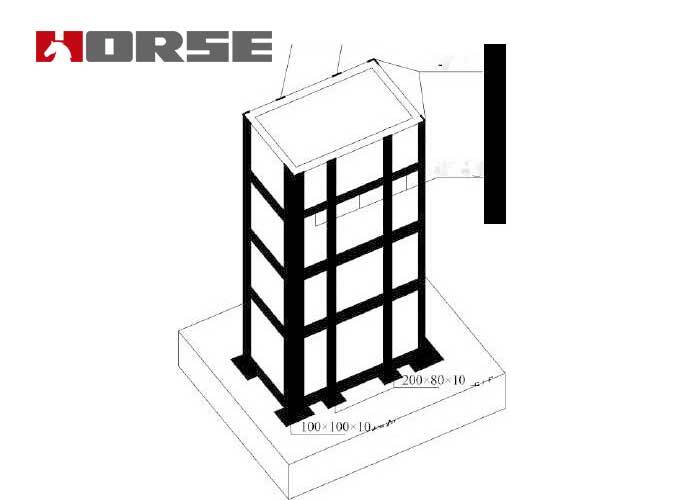

The project adopted an enlarged cross-section reinforcement scheme according to the requirements of a design institute's reinforcement drawings. For the structure of the main factory building @,© axis below 14.65m, the enlarged cross-section method was used for reinforcement.

Design requirements for frame column reinforcement: Increase the cross-sectional dimensions of the original frame column by 100mm on each side, and the reinforced reinforcement is 36 and stirrups 14@100. After cutting out the concrete protective layer, it is required to implant 12@200 in the side planting bar of the frame column.

Calculation of reinforcement column material:

1) No shrinkage grouting material is 10.75 pieces/m.

2) 912 steel bars of 12 of the chemically anchored plant bars, and 36 steel bars of 32 of the chemically anchored plant bars.

3) The amount of steel bars 6 315.5kg/piece.

4) Formwork support and scaffolding 9 668 square meters.

A total of 235,300 yuan per piece.

The clad steel reinforcement plan with enlarged section, angle steel and flat steel hoops

Strengthening column material calculation

1) No shrinkage grouting material 5.28 roots/m3.

2) Reinforced section steel 4 pieces L90x 12, 4 pieces -150xl2, structure clad steel 37 pieces -100x8, 3.54t.

3) Formwork support and scaffolding 9 668 square meters each.

A total of 88,500 yuan per piece.

Conclusion

The above two reinforcement methods can satisfy the structural safety and durability at the same time, but the economic benefits differ by 2.7 times. The project cost a total of 2.938 million yuan to reinforce 20 frame columns. The clad steel reinforcement scheme with enlarged cross-section, angle steel and flat steel box is adopted. In the actual operation on site, the quality of the joint is easy to grasp. The use of this scheme saves materials and labor and obtains better economic benefits. It satisfies the principles of reliable technology, reasonable economy, simple construction and quality assurance, while meeting the requirements of the construction period.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

two-components modified epoxy resin adhesive, with high quality plastic tube, double cartridge package

Two-component epoxy modified epoxy structural strengthening adhesive for bonded steel plate to concrete

Modified epoxy resin structural perfusion adhesive, specifically for supporting adhesive bonded steel reinforcement