Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Cracks In Reinforced Concrete Structures

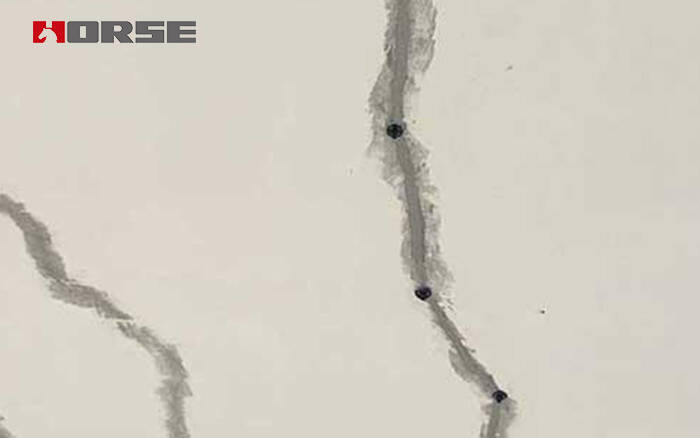

Cracks

Cracks in reinforced concrete structures are always an alarm, indicating that something bad is happening or that there is a major structural problem. Since harmful substances will enter there and start the corrosion process in the steel bars, we associate them with the loss of aesthetics and future durability issues.

Water seepage cracks in underground structures (such as building basements) will greatly shorten the life of the structure due to corrosion and concrete damage, and will reduce its functionality and utilization.

How to solve these problems?

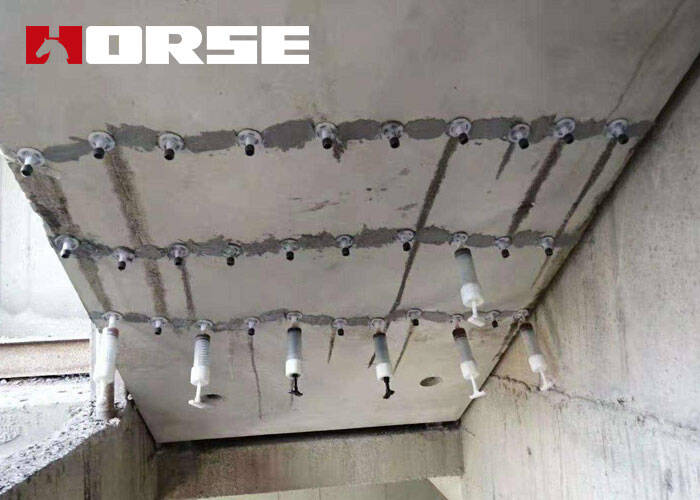

These cracks can be injected to avoid expensive repair costs and damage to the building's finish. Horse offers a wide range of systems and product portfolios for injection according to the type of crack to be treated. These systems can be used at any time at the beginning of construction or later to extend the service life of the structure.

Benefits of using Horse injection system

These are not only used for sealing leaks and waterproofing, but also for restoring structural integrity and load-bearing capacity. As a major requirement, all Horse injection products are fully tested to meet different global standards.

There are several reasons why concrete can crack:

When talking about a new structure, we can mention the following. Too much water in concrete, lack of solidification of concrete, premature removal of formwork, insufficient section of structural elements (beams, columns, slabs, walls, etc.), insufficient amount of steel in structural elements, and poor positioning of reinforcement steel.

When it comes to existing structures, the most common cause of cracking is an increase in service load. These service loads correspond to vertical loads (static and active loads) and final loads, such as loads imposed by earthquakes. Reinforced concrete structures will crack when they are subjected to service loads. This is a normal phenomenon: static load (self-weight and permanent load) and live load (weight of goods and people). As long as it does not exceed the specified crack width, it can be considered normal.

There are several ways to classify cracks.

Depending on their depth, they may be: surface or through;

Depending on the movement, they may be: active or inactive;

And depends on the humidity conditions: dry or wet (pressurized/unpressurized water).

Reasons for crack repair

Durability.

The main reason for sealing cracks in concrete structures is the durability of the structure. Through the cracks, environmental aggressors can enter the steel bars (humidity, carbon dioxide, dissolved substances contained in the soil, dissolved salts (chlorides) in seawater, etc.). Cracks are like open wounds into which disease enters. When environmental invaders reach the steel bars, the corrosion process begins. The rust that appears on the steel bars is a product of corrosion. These corrosion products exert a tensile force on the surrounding concrete, causing it to rupture after a certain period of time.

Impermeability.

It is necessary to prevent water from entering the inside of the structure. Water is one of the necessary reagents for corrosion problems, and corrosion problems make the structure worse. In addition, the design of the concrete structure prevents water from entering the interior and must provide comfort for the occupants (for buildings, houses, etc.).

Rigidity.

When cracks pass through structural elements (beams, columns, slabs, walls, etc.), their stiffness will be affected. Depending on the width of the crack, the component's ability to withstand service loads will be compromised. This is why it is important to inject these cracks and restore the lost integrity.

Conditions for repairing cracks

There are 3 factors that can help us choose the best way to repair a crack: the width of the crack, the movement of the crack and the state of the crack.

The minimum width of the crack is 0.15 mm (the width of a human hair) and the maximum width is 6 mm (for epoxy resin, pressure injected acrylic). The width of the crack determines the viscosity of the product used. For smaller cracks, the viscosity is less, and for wider cracks, the viscosity is greater. It also determines the product to be used; epoxy or acrylic can be used to inject cracks with a width of up to 6 mm. For widths greater than 6mm, grout-type materials become important.

It is necessary to determine whether the crack is active (moving) or inactive (not moving). For active cracks, we choose flexible injection materials with limited elasticity. For inactive cracks, we can choose rigid resins (such as epoxy resins) that can restore section stiffness and integrity.

Is it dry or permanently wet? Is the water in the crack under pressure? The answers to these questions define the type of product to be used and the injection method. For example, for wet cracks (even pressurized water), it is recommended to use a resin that can react with water and expand to seal the cracks and water from entering the structure. These resins can be expandable or non-expandable polyurethanes. The flexible and non-swellable acrylic resin can also come into contact with water to provide a more permanent seal for injection.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Very strong penetration and low viscosity epoxy crack injection adhesive for repairing concrete crack

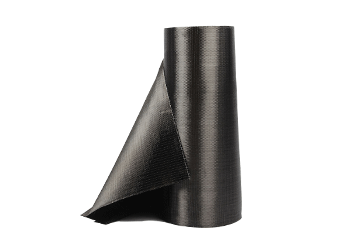

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.

Two-components modified epoxy resin adhesive, with high quality plastic tube, double cartridge package for anchoring