Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Fatal Mistakes In Carbon Fiber Structural Reinforcement

Carbon fiber structural reinforcement has many advantages, and the scope of application of the project is wide. However, if the construction process is not done properly, it will not only not play the maximum role in the reinforcement and repair of the concrete structure, but also waste unnecessary manpower and material resources.

What are the common mistakes in carbon fiber cloth reinforcement construction? How to avoid it?

01

Reinforcement must be carried out according to the principle of first reinforcement and then loading, and unloading treatment must be carried out when necessary (determined by the designer)

02

The degree of surface treatment of reinforced concrete components will directly affect the quality of reinforcement. It is required to sand and level until the new concrete surface is exposed. The corner paste must be polished into an arc shape (R≥20mm), because the right angle will cause stress concentration, which will affect its strength. After polishing, use compressed air to blow off the dust.

03

Before applying the primer, scrub it again with acetone or alcohol to ensure that the bonding surface is clean, so that the carbon fiber and the reinforced concrete components have a good bond, forming an effective composite body. If the surface dirt floating slurry is not cleaned or is not flat enough, or is out of place, it will seriously affect the positive tension bond strength between the carbon fiber cloth composite layer and the concrete, and directly affect the construction quality and reinforcement effect.

04

Carbon fiber cloth must be impregnated with carbon fiber impregnating glue, as far as possible to allow the adhesive to fully penetrate into the gaps between the carbon fiber monofilaments to improve the common working performance between the monofilaments.

05

Strictly control the mixing ratio of dipping glue according to regulations, and stir until the color is uniform. Determine the mixing amount of resin glue according to the actual ambient temperature on site, and control the use time as required.

06

Paste carbon fiber board in the tension area of reinforced concrete beams and slab members for bending reinforcement, and the fiber direction is consistent with the tension direction of the reinforcement. U-shaped paste is used to strengthen beam and column members under shear, and the fiber direction should be perpendicular to the axial direction of the member.

07

Do a good job in the overall construction quality inspection:

▶ Bonding quality: The bonding quality between carbon fiber cloth and concrete can be checked by lightly tapping with a small hammer or pressing the surface of the carbon fiber cloth by hand. The total effective bonding area should not be less than 95%. When the area of the hollow drum of carbon fiber is not more than 100cm², it can be remedied by syringe injection; when the area of the hollow drum is larger than 100cm², it is advisable to cut off the carbon fiber cloth at the hollow drum and reattach the carbon fiber cloth.

▶ Bond strength: Find a qualified laboratory to go to the site to conduct a positive tensile bond strength test, requiring each sample to be concrete cohesive failure.

The sparse or improper construction of the above links will have an impact on the final effect, and the real reinforcement effect of carbon fiber cloth cannot be exerted. Therefore, you must carefully check the links during the construction and earnestly ensure that the construction is in place.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

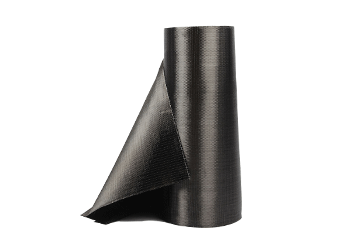

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.