Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Repair And Reinforcement Of Ancient Building Structure

Ancient Chinese buildings are mainly composed of wood, stone, brick and tile. Among them, the tile material should be replaced, the stone has good strength and durability, and the brick masonry is prone to cause scaly, loose, bulging, and wood components are often damaged by grooves, moths, cracks, and crooked flashes. The following introduces several reinforcement measures and methods commonly used for masonry and wood components.

1. Reinforcement measures of masonry

(1) Demolition

When the wall is severely corroded, loosened, hollowed, crooked, and has obvious cracks, which cannot be repaired by picking, digging, repairing, and removing, it should be demolished and rebuilt. Demolition of dangerous old walls should try to follow the prototype system, raw materials, original craftsmanship, and original methods to make the shape, color, and scale consistent with the original wall. For the key parts of the force, under the premise of not affecting the appearance, if necessary, new materials and new technologies can be adopted, or improvement measures such as adding ring beams can be adopted.

(2) Grouting reinforcement

When the wall is cracked, loose, and hollow, it is inconvenient to use the long demolition period, and the preservation of the historical features is unfavorable, pressure grouting technology can be used to reinforce it. Grouting materials generally use cement slurry, or a mixture of cement, fine sand, white ash paste, and structural adhesives such as epoxy resin.

To reinforce the hollow drum wall, drill a 600mm pitch plum blossom-shaped diagonal hole in the wall, and apply high-pressure gas to remove the dust and debris in the brick joints before grouting. The wall should be wetted by pouring clean water to strengthen the combination of mortar and bricks. For the reinforcement of wall cracks, a relatively dilute micro-expansion grout is generally used after the cracks are cleared, and people are slowly injected along the cracks to allow it to penetrate. At the same time, the slurry that leaks out of the wall should be cleaned in time to avoid staining the appearance of the wall. After reaching the strength, the surface of the wall should be trimmed and polished.

If the wall is cracked due to the foundation, the foundation should be treated first, and then the wall should be repaired.

(3) Reinforcement by buttress column method

When the stability and strength of the wall are not enough, the concrete buttress column method can be used to reinforce it. This method is generally used for processing on the inside of the wall without destroying the original appearance of the outer wall. When the front and rear eaves walls are built without biting inside or inside and outside, it is advisable to use the method of hitting reinforcement and the reinforcement of additional buttress columns.

(4) Reinforced mesh cement mortar reinforcement

Reinforcement of internal walls or walls that originally contained powder dust can be reinforced by reinforced mesh cement mortar, which means that both sides of the walls to be reinforced are chiseled off or brushed and cleaned, and then sprayed with mortar or fine-stone concrete. This method can greatly improve the teaching capacity of the brick wall, the rigidity of resistance to displacement and the ductility of the wall.

2. Reinforcement measures of wood structure

(1) Correction

The method is to reset the inclined, twisted, and tenon components without removing the wooden frame, and then perform overall reinforcement. Generally, the ones that can be removed and unloaded should be unloaded, and the wooden wedge and bayonet at the tenon and tenon should be loosened. If there are iron parts, loosen the iron parts. In the process of correction and correction, it should be adjusted in stages according to the actual situation, and the amount of adjustment each time should not be too large. If there is any abnormality during the correction process, stop immediately, find out the cause and clear the fault, then continue construction. The overall skeleton of the framework should be done at the same time to repair the damaged components and return the tenon components.

(2) Outsourcing steel reinforcement

When part of the large wooden frame is drawn out, the joints after the return can be reinforced with outsourcing flat steel. Flat steel should be made into a T-shape. It is not enough to use ordinary inlay patching or trimming maintenance for components with more severe splitting and deterioration (generally the width of the joint is greater than 30 mm). After the wood strips are used for repairing with water-resistant glue, 2~3 flat steel hoops or iron wire hoops are added to the damaged section for reinforcement. Clamping angle steel or flat steel can be used to reinforce the components that are rotten or severely broken at the end of the beam and are inconvenient to replace.

(3) Reinforce the beam by wood clamping and bracing

The supporting ends of wooden beams and human walls are prone to damage such as decay and moth-eaten. If the damage depth of the upper and lower sides of the beam is greater than 1/3 of the beam height but less than 3/5, the clamping can be adopted after calculation. The cross-section and material of the wooden plywood should not be inferior to the original beam, and should be made of air-dried wood with straight texture, no knots and pith. When the clamping construction is difficult, it can be reinforced by bracing.

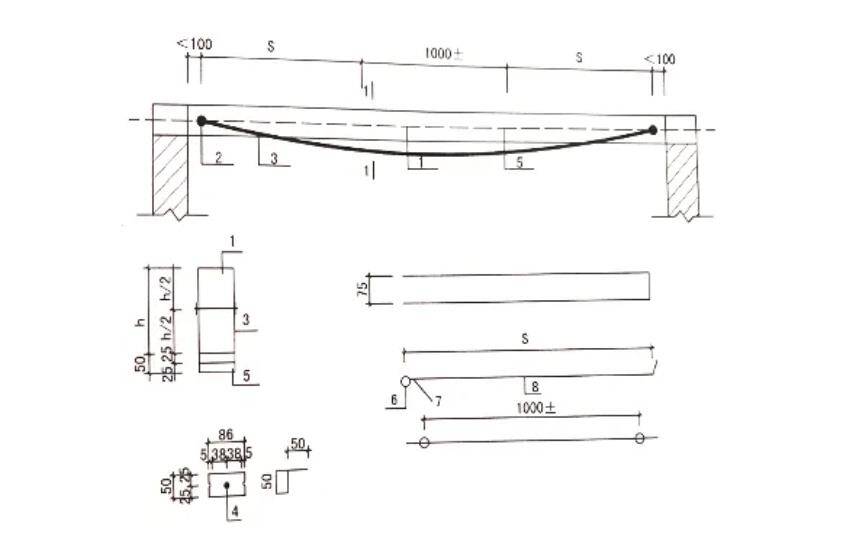

(4) Steel tie rod reinforcement

When the rigidity or bearing capacity of the beam components is insufficient, if signs of fracture are found, or the tensile strength of the lower chord of the roof truss is insufficient, the steel tie rod reinforcement method can be used to strengthen it. Before reinforcement, make sure that the wood components are intact and free from decay and moth-eaten. Note that the tensile force applied when the tie rod is used for reinforcement should be appropriate.

(5) New chemical reinforcement

By adopting the new chemical indiscriminate reinforcement technology, the components with more than 1/3 of the grooves and moths can be reinforced without replacing them, and they can be overhauled without falling off the shelf.

(6) Carbon fiber cloth (CFRP) and structural adhesive reinforcement

Carbon fiber is widely used in the reinforcement of reinforced concrete structures due to its light weight, high strength, good plasticity, corrosion resistance, good durability, excellent construction performance and wide applicability. Based on these properties, it is the material of choice for the reinforcement of traditional wooden members with irregular sections.

Because the fiber cloth is very light and thin, the reinforced wood components will not affect the appearance at all after being painted, and there is almost no additional weight added. It can replace the iron hoops in the traditional reinforcement method. Not only is the strength much higher, the construction is extremely convenient, and there is no need for anti-corrosion treatment, and it can also protect the wood from corrosion.

Chemical grouting filled wood components, if supplemented by carbon fiber cloth wrapping around, can greatly improve its bearing capacity. Modern materials such as structural glue and matching fillers mixed with wood chips are used in the filling, embedding, and trimming of small cracks in wooden components, which are simpler, faster and more effective than traditional maintenance methods.

(7) Replace with new components

When the wooden components are severely decayed, moth-eaten, burned or cracked and cannot be repaired and reinforced, new components can be considered (generally the falling frame is dismantled and replaced). When the original component has insufficient bearing capacity, the deflection exceeds the specification limit, and cannot be repaired and reinforced, it should be replaced.

The value of cultural relics lies in their existence. Only by preserving cultural relics can they reflect their historical, artistic and scientific value. Therefore, strengthening the damaged ancient buildings and extending their life is a key link in the restoration of ancient buildings. The ancient buildings carry the long-standing traditional culture of our country, so the protection of ancient buildings has extremely high practical significance.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

two-components modified epoxy resin adhesive, with high quality plastic tube, double cartridge package

Two-component epoxy modified epoxy structural strengthening adhesive for bonded steel plate to concrete