Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

What Are The Tips For Sticking Steel Reinforcement Construction?

The structural bonding steel reinforcement method refers to the use of a special structural adhesive to paste the steel plate on the surface of the concrete member with the building structural adhesive to make the steel plate and the concrete form a whole to achieve the purpose of strengthening and enhancing the strength and rigidity of the original structure. Below we will share with you some tips that may be used in construction of bonded steel reinforcement.

Determine the thickness of the steel plate

Considering the safety of the structure as a whole, and controlling the cracks and deformation of the reinforced components, the reinforcement of the steel plate attached to the tension zone and the compression zone during construction should not exceed 3 and 2 layers respectively. The total thickness of the steel plate should not should be greater than 10mm.

Paste the steel plate

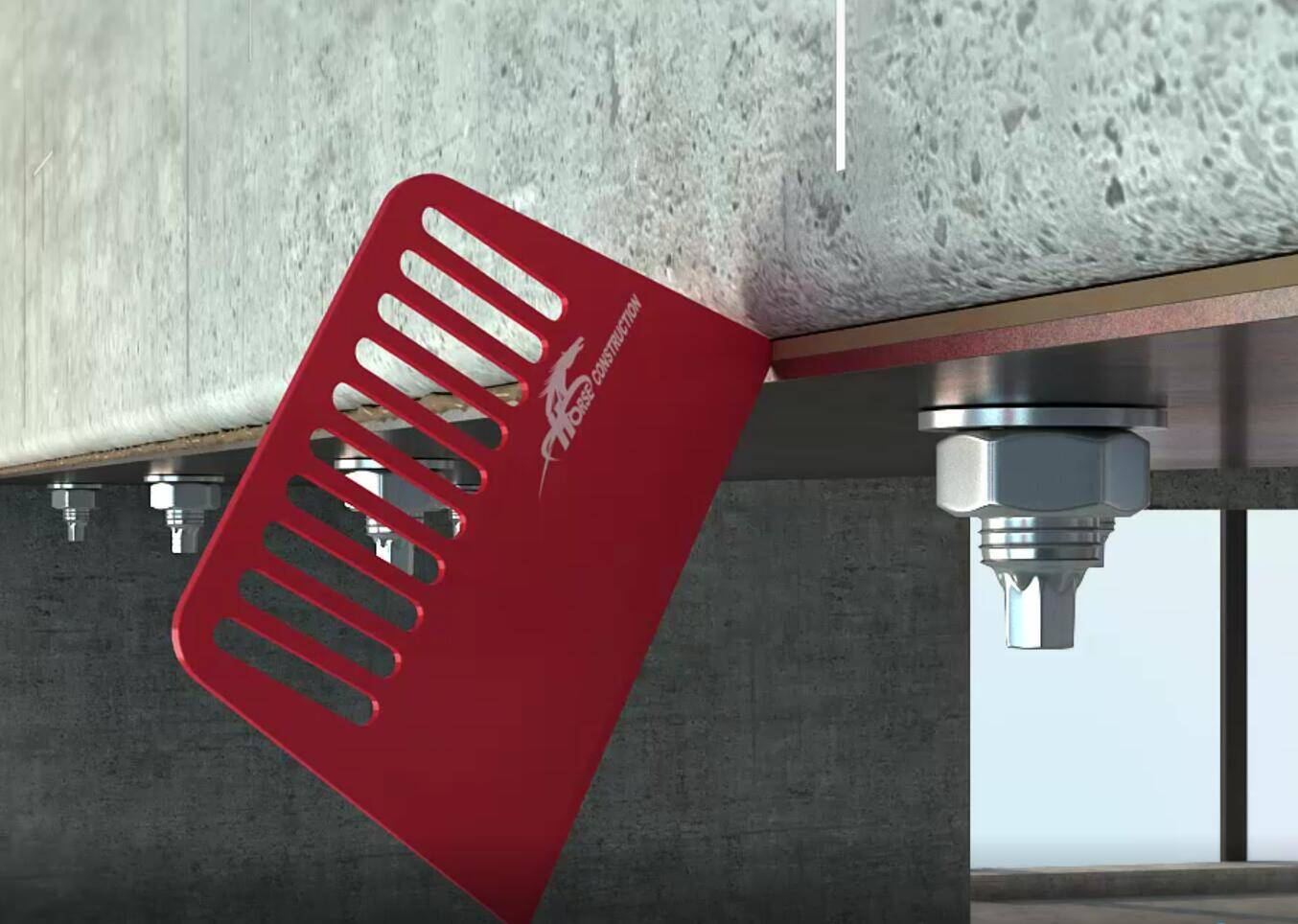

At the present stage, most of the steel-bonding construction uses bolts to pressurize and fix it, and it can also use the method of drilling holes in concrete members or steel plates. The original roof support method is now rarely used.

drilling

When drilling holes, the location of the original steel bars in the concrete should be ascertained first, and avoidance should be made when marking and positioning. If it is difficult to find out, or if you have encountered steel bar obstructions when drilling, it is allowed to move 2d (d is the diameter of the hole) and re-drill, but the waste hole must be filled with reinforcement glue. The drilled hole should use compressed air to blow away the dust and debris in and around the hole. If the moisture content of the concrete on the hole wall exceeds the limit, it is advisable to use an electric heating rod to hang into the baking hole wall or to fill it with glue that can hold water.

Trial assembly

The bonding interface of the steel plate and concrete should be cut and processed first, and then the trial assembly should be carried out according to the requirements of the reinforcement drawing and the actual size. This work is very important because the adhesive has a limited operating time and cannot be easily adjusted or changed after curing. Therefore, all operations related to drilling and positioning should be checked and corrected during the trial assembly process.

Sticky steel glue mixing

The special structural adhesive for sticking steel plates should be formulated and used in accordance with the regulations of the product manual. When mixing the adhesive, a low-speed mixer should be used to fully stir. The color of the mixed glue should be uniform and free of bubbles, and the mixing of water, oil, dust and other impurities should be prevented.

Adhesive layer thickness

The mixed glue should be applied to the bonding surface of the steel plate and concrete at the same time, and the steel plate can be pasted with the original component concrete after checking that there is no missing brush; the average thickness of the glue layer after pasting should be controlled within 2mm~3mm. When laying down, the glue layer should be thick in the middle and thin at the edges; when sticking vertically, the glue layer should be thick at the top and thin at the bottom; when sticking upside down, the sag of the glue should not be greater than 3mm.

Pressurize

When the steel plate is pasted, the surface should be kept flat, the transition of the level difference should be smooth, and there should be no corners. After the steel plate is pasted, it should be evenly distributed and fixed under pressure. The pressure sequence should be from one end of the steel plate to the other end point by point, or from the middle of the steel plate to the two ends; the pressure must not be applied from the two ends of the steel plate to the middle.

Pressure fixation can be used: clamp pressure method, anchor bolt (or screw) pressure method, support top pressure method, etc. The distance between the pressure points should not be greater than 500mm. When pressure is applied, it should be adjusted according to the thickness of the glue line between 2mm and 2.5mm.

Bonded steel construction quality inspection

The bonding quality between steel plate and concrete can be inspected by hammering method or other effective methods. The effective sticking area estimated according to the inspection results should not be less than 95% of the total sticking area.

During inspection, the pasted steel plates should be divided into sections, and the area of the hollow drum (that is, invalid pasting area) should be measured area by area. If the area of a single hollow drum is not larger than 10000mm2, it can be repaired by drilling and injection method. If the area of a single hollow drum is larger than 10000mm2, the reposting should be removed, and the inspection and acceptance should be performed again.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Two-component epoxy modified epoxy structural strengthening adhesive for bonded steel plate to concrete

Modified epoxy resin structural perfusion adhesive, specifically for supporting adhesive bonded steel reinforcement