Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Analysis of several structural reinforcement methods and construction key points about opening holes in floor slabs

After the opening of the floor slab, the original force transmission path and reinforcement are partially cut off. On the one hand, the internal force of the slab around the opening is increased, which will cause stress concentration. On the other hand, the plate ribs are reduced and the bearing capacity is reduced, and effective reinforcement is required according to the actual situation.

When the width of the hole b ≤ 300 mm or the hole diameter D ≤ 300 mm perpendicular to the force direction of the slab, and the number of cut steel bars ≤ 5%, no treatment is required. When b≤1000mm or D≤1000mm, the number of cut steel bars is ≤20%, and the force impact on the slab after opening the hole is small, and only the structure is reinforced, the compensation reinforcement method can be adopted. Add the cut steel bars in the slab to the edge of the hole. In order to facilitate construction, bonded steel or carbon fiber cloth is generally used as the back compensation rib, and the total amount should be ≥1.2. When the above conditions are exceeded, it is necessary to adopt suitable steel edge beams or cast-in-place concrete edge beams for reinforcement through design calculations.

Carbon fiber reinforcement

The cast-in-place continuous slab has holes. When the hole is located in the negative bending moment area of the slab, when the bonding carbon cloth is used for reinforcement, double-sided reinforcement should also be carried out. The order of the vertical and horizontal fiber cloth paste is not restricted.

related requirements:

a. The specification of carbon cloth is 200mm~300mm wide and 200g~300g quality.

b. This reinforcement method can only be used for structural reinforcement because the opening is small.

c. The maximum tensile value of the compensation carbon cloth shall not be less than 1.2 times the equivalent tensile value of the truncated steel bars.

d. When the carbon cloth is in contact with the steel plate, a layer of adhesive should be applied instead of direct contact.

Bonded steel reinforcement

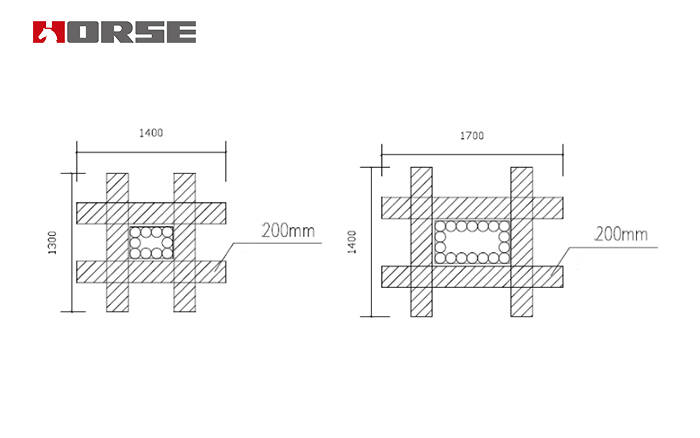

The cast-in-place continuous slab has holes. When the hole position is located in the negative bending moment area of the slab, when sticking steel is used as compensation reinforcement, it should be reinforced on both sides. For the sticking steel plate reinforcement method, the direction of the greater force should be pasted on the outermost layer (which means that the last is pasted), and the steel plate of the direction of less force should be pasted on the inner layer (the first to be pasted). At this time, the first-bonded steel plate should be grooved at the concrete veneer. The thickness of the groove is ≥ the thickness of the steel plate + 3mm to ensure that the surface of the first-bonded steel plate is flush with the floor of the floor. It can also be glued in two directions, but it is necessary to cut the steel plate in the direction of less force into three sections, weld on site, and pour adhesive after partial.

related requirements:

a. The steel plate selection specification should be 100mm~200mm wide and 3mm~5mm thick.

b. This reinforcement method can only be used for structural reinforcement because the opening is small.

c. The area of the compensation steel plate shall not be less than 1.2 times the equivalent cross-sectional area of the truncated steel bar.

Bonded steel and carbon fiber reinforcement commonality

Whether it is plate steel or carbon cloth that bears the negative bending moment, it will be blocked by the wall and cannot be penetrated. At this time, the screw and short angle steel can be used to pass through the wall to tie and anchor the tension. For the frame structure cast-in-situ floor slab with openings in the corner area and bearing the negative bending moment, the plate steel or carbon cloth shall be bent and anchored on the outside of the side beam, and meet the anchoring length requirements.

When opening holes for cast-in-place floor slabs, the stiffness and strength of the opening floor slabs will be weakened to varying degrees when not opening holes. Generally speaking, the weakening of rigidity is more obvious, and there will be greater stress concentration on the short side or corner of the hole, and the reduction of slab gluten will result in the reduction of bearing capacity. Therefore, after the internal force analysis and bearing capacity calculation of the floor after the opening are carried out, appropriate reinforcement treatment methods shall be adopted according to the properties of the floor, the opening position (edge, middle), the size and shape of the opening, and so on. Floor properties include (beam floor, beamless floor, simply supported slab, continuous slab, one-way slab, two-way slab)

When using these two methods, it is necessary to pay attention to the double-sided reinforcement at the upper and lower sides of the plate when opening holes in the negative bending moment area of the plate, and at the same time ensure the anchoring measures at the ends.

Add concrete side beams

When the slab opening is further expanded, causing the width or diameter of the opening to be greater than 1000mm, or the number of cut steel bars exceeds 20%, and when there is a large concentrated load at the opening, the prefabricated slab cuts the main rib, etc., only carbon fiber cloth or steel plate is used. The reinforcement effect will be very limited, and the force transmission path should be changed to reduce the adverse effect of stress concentration on the force of the floor. To change the stress transfer, new beams at the opening can be used for support transfer. When using this method, it is necessary to pay attention to whether the frame beams of the original structure need to be strengthened in the vertical and horizontal directions, and to ensure the effective transfer of shear force.

Additional steel beams

Generally, the back-cut hole needs to be flanged, and the steel bar of the hole is cut and bent upward, and the edge of the hole is chiseled to make the flanging. The height of the flanging is not less than 100mm, the thickness is not less than 80mm, and the strength level of the flanging concrete is not less than that of the original concrete slab. The steel beam placed on the edge of the hole can be I-beam, channel steel or angle steel, and the specific amount is determined by calculation.

The connection between the steel beams is connected by ordinary bolts or high-strength bolts.

Attention should be paid during construction: the opening of the hole must be lightly hit, and no heavy hammer shall be used to prevent the edge of the hole from cracking; the whitewashed layer of the floor must be removed. In order to make the reinforced concrete and the steel beam close, a steel frame is driven between the steel beam and the floor slab, and the steel wedges are driven into the steel beam by electric welding.

No matter the size of the hole in the floor slab, it will have a certain impact on the structural integrity and cause certain damage to the bearing capacity of the floor. Only by attaching importance to the later reinforcement treatment and choosing appropriate reinforcement technology and high-quality and safe reinforcement materials can the structural safety be ensured in the long run.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.