Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Analysis On The Construction Points Of Multi-layer Bonded Steel Reinforcement

Due to the increase of service life and the change of function of the structure, the durability will be reduced, the bearing capacity will be insufficient, and eventually structural diseases will occur. In recent years, with the intensification of the aging of buildings in my country, including structures such as houses, bridges, and tunnels, the incidence of diseases is showing an upward trend. The rise of structural reinforcement has brought solutions to diseased structures and is of great significance to the sustainable development of resources.

Bonded steel reinforcement and carbon fiber cloth reinforcement have a high degree of similarity, so the two are often referred to and compared with each other. In the reinforcement of carbon fiber cloth, there are multiple layers of paste. Is it also applicable to the reinforcement of bonded steel?

01

Determination of stick steel thickness

In bonded steel reinforcement, the thickness of the reinforced steel plate is directly related to the increase in the bearing capacity of the section. The calculation process of the thickness of the steel plate is similar to the calculation of the amount of steel bars in the reinforced concrete structure.

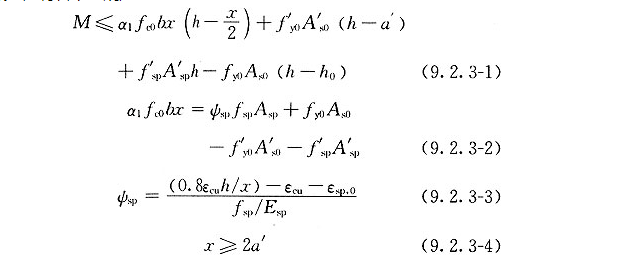

When steel plates are used to reinforce concrete flexural members (such as concrete beams), it is first necessary to obtain the height of the concrete compression zone from the bending moment value of the reinforced member. Then calculate the cross-sectional area required for strengthening the steel plate through the height of the compression zone. Finally, the reasonable steel plate width is determined according to the beam width, and the required steel plate thickness is calculated. The following formula is taken from GB50367-2013 "Code for Design of Reinforcement of Concrete Structures".

After the above calculation process, the thickness of the steel plate can be verified, but it does not mean that the thickness of the steel plate can be increased indefinitely to increase the structural bearing capacity without limit. If the steel plate is too thick, it is easy to cause the splitting damage of the bond between the steel plate and the concrete base material, which makes the reinforcement fail. On the other hand, considering the overall safety of the structure and the control of cracks and deformations of the reinforced components, the thickness of the steel plate should not be greater than 10mm.

02

Analysis of Multilayer Bonded Steel Strengthening

From the requirements of the thickness of the steel plate, we can see that the multi-layer steel plate is more restrictive than the multi-layer carbon cloth. For steel plates, whether it is a single-layer steel plate or a multi-layer steel plate, there is also a maximum thickness limit of 10mm. Why should a multi-layer steel plate be used? This is because according to a lot of engineering experience, it is not suitable to use manual construction for steel plates with high thickness. The specification also requires that the thickness of the steel plate to be glued manually should not be greater than 5mm. If it is greater than 5mm, the form of pressure gluing should be used, which is similar to the reinforcement method of externally bonded steel.

That is to say, when we calculate that the 5mm thick steel plate cannot meet the reinforcement requirements, if we want to use the form of single-layer steel plate, we need to use a glue injection machine for glue injection construction. Compared with conventional bonded steel reinforcement, it is slightly more complicated. Multi-layer sticking of steel can make up for this problem to a certain extent, and it is also used more in actual operation.

However, whether the multi-layer bonded steel can achieve the desired effect is still open to question. Similar to multi-layer carbon cloth, the strength provided by the steel plate will be reduced from the second layer (including the second layer) of the multi-layer bonded steel. Caused by the same 10mm thickness, the strength provided by multi-layer bonded steel is lower than that provided by single-layer bonded steel. When the flexural member is bonded to the steel plate, the two ends of the steel plate will generate stress concentration due to the edge effect, which is the weakest part of the bonded steel, especially for the multi-layer bonded steel. Therefore, in the reinforcement of multi-layer bonded steel, it is necessary to attach great importance to the anchoring measures at the end of the steel plate to prevent peeling damage.

Multi-layer bonded steel reinforcement is also a test for the bonded steel glue used. The properties of the colloid are directly related to whether the steel plate can form a whole with the base material, and that the peeling damage does not occur between the steel plate and the steel plate. On the whole, the Horse adhesive steel adhesive that has passed the safety appraisal has better bonding performance and can provide a more secure guarantee for the reinforcement of adhesive steel.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High-strength anchor bolt with vinyl resin as main materials, composed of selected quartz sands, curing agents and glass tubes

Two-component epoxy modified epoxy structural strengthening adhesive for bonded steel plate to concrete

Modified epoxy resin structural perfusion adhesive, specifically for supporting adhesive bonded steel reinforcement