Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Concrete Compressive Strength

Concrete strength generally refers to: compressive strength, tensile strength, shear strength, etc. The following is the introduction of concrete compressive strength.

The commonly used methods for testing the compressive strength of concrete by housing safety appraisal agencies include rebound method, comprehensive method, core drilling method, etc.

Rebound method

Measure the surface hardness of concrete using a rebound instrument, and then infer its compressive strength based on the carbonation depth of the concrete. The rebound value measured by the rebound instrument is the hardness of the concrete surface, and the hardness of the material is related to the strength of the material. Therefore, a dedicated strength measurement curve for rebound value and strength is established to infer the strength value.

advantage

1. It is simple and flexible to use, with fast testing speed and low inspection costs.

2. The testing personnel randomly select and test the concrete on site, and timely grasp the true strength of the concrete and the overall level of pouring.

shortcoming

1. The accuracy is relatively poor and requires the use of a certain strength measurement curve.

2. When there is a significant difference in quality between the surface and interior of the concrete, such as chemical corrosion or fire, frostbite during hardening, etc., this method cannot be used.

Ultrasonic method

Using many characteristics of ultrasonic (such as reflection and diffraction), through observing the propagation changes of relevant ultrasonic waves displayed on the Ultrasonic testing instrument, determine whether there are defects in the interior and surface of concrete, so as to evaluate the quality without damaging or damaging the tested materials and workpieces.

advantage

Ultrasonic testing can make more accurate judgments on the location and range of cavities and non dense areas in concrete, crack depth, thickness of surface damage layer, bonding quality of concrete poured at different times and concrete homogeneity.

shortcoming

There are many factors that affect the speed of sound, such as cement variety, cement dosage, sand content, coarse aggregate variety and maximum particle size, moisture content, age, etc. When the materials used, moisture content, and age are different, the relationship between the propagation speed and the strength of concrete will be greatly different. Therefore, it is difficult to accurately measure the strength of concrete using ultrasonic methods.

At present, it is common to combine the ultrasonic method and rebound method to determine the strength of concrete, which is called the ultrasonic rebound comprehensive method (a single ultrasonic method mainly tests the uniformity of concrete).

Core drilling method

On representative concrete structures, core samples are drilled using a diamond drill bit, processed, sawn, ground or patched at both ends, and then made into cylinders for compressive strength testing. Concrete with a component age of no less than 14 days and a strength of no less than 10MPa can be tested for strength using the core drilling method.

advantage

1. The core drilling method is a local damage detection method that directly reflects the actual situation of component concrete, and can accurately measure its strength.

2. The actual situation of the concrete inside the component can be directly observed from the extracted core sample, such as aggregate distribution, honeycomb pores, cracks, etc.

shortcoming

1. The labor intensity is high, and the sampling process and core sample processing requirements are high.

2. The flatness requirement for both ends is very high, and if uneven, it will cause low strength and local damage to structural components.

3. The testing cost is high, and the component steel bars are too dense to be extracted.

summary

1. If more accurate determination of concrete strength is needed, the core drilling method can be prioritized;

2. If the quality of concrete is relatively stable, the rebound method or ultrasonic rebound method can be used, and then the test results can be rechecked through the drilling core method, which can greatly improve the accuracy and strength of the above two detection methods.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

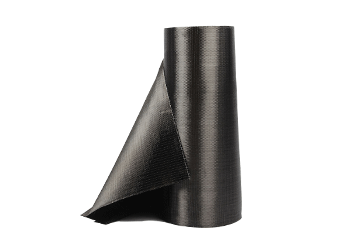

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.