Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

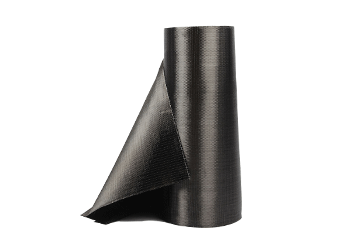

Carbon Fiber - Carbon FIber Fbric

Carbon fiber is a fiber filament obtained by heating an organic material with carbon as the main component in an inert gas environment. Carbon fiber fabric contains at least 90% of carbon, which is obtained by specially controlling fiber pyrolysis. Carbon fiber has high corrosion resistance, such as acidity, openings and materials. Carbon fiber reinforced polymer (CFRP) is usually made of two carbon wrapping materials (carbon fiber cloth or carbon fiber fabric). The first is a one-way carbon package, the carbon fiber is parallel to the zero degree direction, and the second is a two-way carbon package, the carbon fiber is in two directions, zero and perpendicular to it (90 degrees). Carbon packaging is used in many fields, such as building renovation, defense industry, automobile industry and many other important industries. Carbon fiber coating materials usually use materials such as epoxy resin and FRP thixotropic epoxy adhesive to improve the load-bearing capacity of the structure and improve the shear, bending and bending resistance of the components.

Carbon fiber fabric

The mechanical properties of carbon fiber fabrics such as light weight and high resistance make it widely used in the composite material industry and structural seismic reinforcement. One of the most important advantages of carbon fiber fabrics is their light weight and high tensile strength.

Carbon fiber is one of the most widely used fibers in the composite material industry. This fiber has the greatest tensile strength among other types of fibers (glass fiber and aramid fiber). The linear expansion coefficient of carbon fiber is low at both high and low temperatures, resulting in the dimensional stability of the carbon fiber coating at different temperatures. Among the various advantages of carbon fiber (and subsequent carbon packaging), the most prominent ones are tensile strength and light weight (carbon is about one-third the weight of steel, and 5 to 10 times the weight of steel). In addition, carbon fiber has good fatigue resistance. Carbon fiber's durability, chemical resistance, long life and X-ray opacity are one of the most outstanding properties of carbon fiber. In addition, carbon fiber fabric has excellent electrical conductivity, fabric texture and manufacturing capabilities, the manufacture of lightweight composite materials and solid carbon fiber reinforced plastics, and its heat resistance, which distinguish it from other engineering materials. The price of carbon fiber is due to its long life and provides high durability. Over time, the cost-effectiveness and economic aspects have become more and more significant.

Carbon fiber fabric performance

Low weight

High tensile strength of carbon fiber

High elastic modulus

Carbon fiber with low expansion coefficient keeps the fiber length constant at different temperatures

High corrosion resistance

Non-explosive properties of carbon fiber

Anti-fatigue

Good flexibility

Easy to shape, good structure

Light weight, high strength, high modulus, corrosion resistance, good electrical conductivity

High strength and low weight

Minimal changes to the shape, weight or appearance of the structure

Corrosion resistance

Thermal compatibility

Good flexibility, conform to any shape

Good fatigue performance

Repair faster than other methods

No need for welding and heavy equipment

There is almost no interference and noise during preparation or installation

Low total cost

Advantages of carbon fiber fabric

Light weight, density is only 1/4 of steel;

High strength, the thickness of the fabric does not exceed 1 mm, does not increase the weight and section size of the original structure, and has a reinforcing effect;

Highly flexible, can closely cover special-shaped structures, and can be operated in small spaces;

Easy to use and efficient, no need for large machinery, tools or wet construction;

It has strong applicability and can be used for the reinforcement of various concrete, masonry and wood structures;

It has the characteristics of corrosion resistance, acid resistance, alkali resistance, salt resistance and other harsh environments;

No pollution, non-toxic and tasteless;

Application of carbon fiber fabric

Application of carbon fiber fabric in construction industry. Use carbon fiber composite materials to reinforce buildings and structures. Fabrication of plates and carbon fiber sheets, construction of post-tensioned carbon fiber in concrete structures.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.