Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

bonded carbon fiber for reinforced concrete structure

I. Overview

When entering the 21st century, the biggest challenge facing the construction industry worldwide is the aging damage of civil engineering structural infrastructure.

The main reasons for this dilemma are:

(1) A large number of bridges and buildings have reached the service life of the original design;

(2) The destruction over time and the deterioration of the environment continue to accelerate;

(3) The original facility design and raw material selection are restricted by the technical conditions of the time, which caused the original facility performance to be poor;

(4) In the event of floods, fires, earthquakes and other disasters, the structure and components are subject to non-destructive internal injuries, or the reinforcement of the reinforcement is oxidized and the strength of the components is reduced;

(5) Due to human factors, the concrete structure cannot meet the requirements of the building code;

(6) The concrete structure that has been used for a long time lacks formal testing, necessary daily maintenance and maintenance, which also leads to potential danger.

The problems in my country's buildings are mainly manifested in the following aspects:

(1) There are many dangerous buildings. According to statistics from 1980, there are about 30 million square meters of dangerous housing in more than 200 cities in my country, accounting for 0.7% of the total housing area. Among them, Shanghai has 540,000 square meters. Chongqing has 90,000 square meters and Beijing has 2 million square meters. In industrial buildings, dilapidated buildings are 3 million square meters, accounting for 3% of industrial buildings. According to a survey of key iron and steel enterprises in 1983, there are still 3 to 3.5 million square meters of Class III buildings, including 3o-145 thousand square meters of dangerous buildings.

(2) There are many collapse accidents. Looking back, there have been three times when there were many collapse accidents. The first time was during the "Great Leap Forward" in 1958, the second was during a decade of turmoil, and the third was in the early 1980s.

(3) As for bridges, as of 1998, there were 210,822 highway bridges nationwide, including 3053 temporary bridges and 4105 dangerous bridges. The number of temporary bridges and dangerous bridges on national and provincial roads reached 405 and 1,253, respectively, accounting for 13% and 31% of the total number of temporary bridges and dangerous bridges.

Second, the current situation and prospects of concrete structure reinforcement technology

In the design of civil engineering buildings in the new century, concrete structures will still be the mainstay. Although steel structures, including steel-concrete concrete and steel-tube concrete structures and glass curtain wall structures, there will also be new developments in high-rise buildings and large-span buildings everywhere. The development of concrete structures in the new century depends to a large extent on the development and application of new materials.

Therefore, new requirements are put forward for the materials, and new challenges are issued. In summary, there are the following four aspects:

(1) Not only require high strength of newly poured concrete, but also high performance, including: ductility of concrete, good workability and durability of use.

(2) It is required to find a kind of anti-corrosion reinforcement material to replace the medium-low strength steel bar high strength steel wire and steel grain line in the concrete structure.

(3) For the reinforcement and repair of existing concrete structures, it is convenient to construct and improve the bearing capacity of the reinforced concrete structure.

(4) Starting from environmental protection and sustainable development, it is required that waste concrete can be recovered and recycled.

3. Existing reinforcement methods

(1) Enlarged section reinforcement method: The enlarged section reinforcement method is to increase the load-bearing capacity of the original member by adding reinforced steel bars and re-casting concrete on the outside to increase the section size of the member. The advantage is that it can increase the stiffness, bearing capacity and deformation capacity of the component at the same time. In some cases, the reliability of the connection can also be enhanced.

(2) Outsourcing steel reinforcement method: Outsourcing steel reinforcement method is to use beam cement, epoxy resin chemical grouting or welding to reinforce beam-column outsourcing steel. This method mainly improves its bearing capacity and deformability by restraining the original components.

(3) Prestressed reinforcement: The method of prestressed reinforcement is to apply prestressing to the members through prestressed steel bars to bear part of the load on the beams, roof truss and columns, thereby increasing the bearing capacity of the members.

(4) Steel-bonded reinforcement: Steel-bonded reinforcement is the use of a special building structural adhesive to bond steel plates on the surface of concrete members, which is a reinforcement method to improve the structural bearing capacity and deformation capacity. Its advantages are simple and fast, and it has little impact on life activities and residents' life during construction.

(5) FRP reinforcement: FRP reinforcement is a composite material. FRP can be pasted on the bottom and sides of the beam to enhance the bending and shear bearing capacity of the reinforced concrete beam and improve the beam deformation performance.

4. Technical characteristics and economic analysis of carbon fiber reinforced concrete structures

4.1. Material technical characteristics

(1) Performance is related to the direction of reinforcing fibers

(2) Laminate performance can be tailored

(3) Excellent fatigue performance

4.2. Material price analysis

The materials used in the carbon fiber cloth reinforced concrete structure technology are mainly carbon fiber cloth and bonding materials. Current research and application trends can predict that with the advancement of technology and the nationalization of carbon fiber materials, the material cost of carbon fiber cloth reinforced structural technology will be greatly reduced in the next few years.

4.3.Compared with the original reinforcement method, the technical advantages of carbon fiber reinforcement technology

(1)Easy installation

(2)Corrosion resistance

(3)Short construction period

(4)No maintenance required

(5)Light weight, no influence to original structure

(6)Low cost, cost effective compared with other methods

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

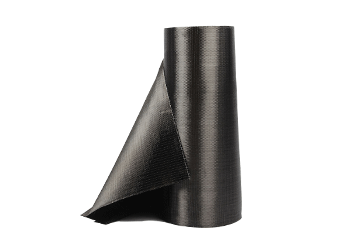

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.