Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Carbon fiber price

Carbon fiber is a new type of reinforcing material for structural strengthening, which has been widely used in recent years. However, the price of each manufacturer varies greatly, and it has always been a confusing and headache for people in the industry and customers to choose. Seemingly similar carbon fiber, the price may be very different, and customers can not find a clear difference at first glance, so many people often choose cheaper products under the psychological effect. As everyone knows, there may be huge secrets in places that ordinary people cannot see. What factors influence the price of carbon fiber? What hidden secrets are behind of the price of carbon fiber? Which carbon fiber should I choose?

Today, Horse construction as the manufacturer of structural strengthening answers your doubts from several possible factors that affect the price of carbon fiber:

1. "Steal" yarn

Many customers are puzzled: the two manufacturers engage in publicity, the raw materials are imported Toray carbon yarn, why the price difference is so much? This may involve "stealing" yarn.

What is "stealing" yarn? This "stealing" and "not stealing", in the reinforcement industry, "stealing" represents a reduction, which means that manufacturers reduce the cost by reducing the use of carbon fiber tows in the production process, thereby reducing pricing.

For example, a standard 300g/m2 carbon fiber cloth has about 37 bundles of yarn at 10 cm. If the manufacturer cuts corners and cuts the weight, the 10 cm uses only 35.5 bundles of filaments, and the 1.5 bundles of filaments are reduced, so the cost is reduced by 4%. This number is not large, and it doesn't feel much. If the production is long-term and mass-produced, the cost savings will be considerable, and it's no wonder that some manufacturers will fight for it. It saves costs and pits customers. This is irresponsible behavior and is not conducive to the healthy development of the industry.

How to discern the existence of "stealing" yarn acts by manufacturers With fewer tows, the corresponding weight is lighter. In comparison, the results are immediately apparent.

2. the large tow replaces the small tow

The inferior carbon fiber has poor hand feel, high hardness, thick and dense, and poor impregnability with glue. In order to reduce costs, manufacturers may use large tow carbon filaments. Because small tows are more expensive, small tow carbon fibers require strict process control, the cost of carbonization equipment is high, and the cost of producing carbon fiber is high.

The cost of using large tows has come down, but it is very dangerous for structural reinforcement.

This is because the tensile strength of the small tow is very stable, the dispersion is very small, the coefficient of variation is below 5%, and the glue is easy to penetrate, so its performance and quality are easy to control in production and use; The beam variation coefficient is as high as 15% to 18%, or even greater, and the reliability is poor, so it cannot be used.

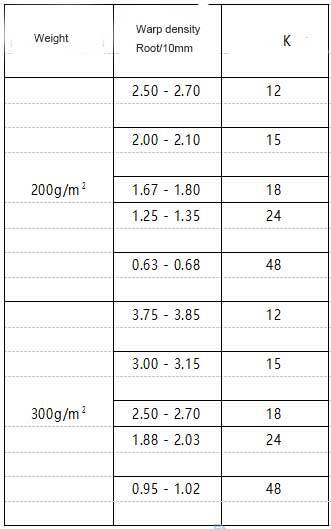

High-quality carbon fiber cloth is usually produced with a standard of 12k-24k. Don't know the k number of carbon fiber you purchased? It doesn't matter, Horse teaches you a way to quickly determine the k number of carbon fiber.

3. Poor performance of poor carbon fiber cloth

Inferior carbon fiber filaments generally show that the tension of the carbon fiber tow is insufficient, the gap between the carbon fiber tows is inconsistent, and the carbon raw material is poor.

Carbon wire tension is not enough: after the glue is cured, some carbon wires are straight, some are not straight, and the tension is not enough to form an empty drum; When the glue drops, the wavy area becomes a falling point, also known as the empty drum;

The gap between the carbon filaments is inconsistent: there is a certain gap between the carbon filaments. If some filaments are tight, they are stuck together, and some filaments are loose.

Poor carbon fiber raw materials: Without good raw materials, there will be no good finished carbon cloth, and it is inevitable to paste to produce empty drums.

Using high-quality carbon fiber cloth is also a way to save engineering costs. Although the low-quality carbon fiber cloth is cheap, it is easy to cause empty drums, and the amount of glue stored in the empty drums is large, so the overall amount of glue used in the project also becomes larger, which seems to save money and the actual cost is higher.

From the perspective of customers, it is natural that the cheaper the better. However, as a manufacturer, customers should not use the psychology of customers to take measures to reduce product quality to lower prices. "Customers who leave because of price may return; customers who leave because of quality will never return." This old saying that is so vulgar can't be more vulgar, but it reveals the long-term survival of a brand. In a turbulent market, an excellent reinforcement material brand is not about low prices, but about quality and service. Only with a product that can stand the test, an innovative and enterprising mindset, and an attitude of doing things practically will you truly win the respect of customers and truly be a leading brand of reinforced materials.

Horse always believes that those who will eventually occupy the market for reinforcement must be those who are dedicated to operating the brand, sticking to product quality and service quality, and paying attention to consumer reputation. And consumers are willing to pay higher prices for good brand products, which is not only a guarantee of safety, they also trust the seriousness and technical maturity of this manufacturer.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.