Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

carbon fiber strengthening system

Principle of carbon fiber strengthening system

Carbon fiber strengthening is another new type of structural strengthening technology after bonding steel and enlarging the concrete cross-section. The working principle is to paste the carbon fiber wrap with epoxy resin on the surface of the concrete structure to form an integral body with the original structure, jointly bear the load, and effectively strengthen the structure.

When should carbon fiber strengthening be used? When is it inappropriate to use?

1. Carbon fiber strengthening is suitable for strengthening of reinforced concrete under bending, axial compression, large eccentric compression and tension members.

2. However, it should be pointed out that because of the inherent stress characteristics of carbon fiber reinforced components, many concrete components are not applicable, mainly in the following three situations:

Stiffness question

When structures such as concrete buildings and roofs lack rigidity, resulting in excessive deformation and severe cracking, which affect the use, it is not suitable to stick carbon fiber wrap for strengthening. Studies have shown that for beams, plates and other transversely stressed members, when carbon fiber is used for strengthening, under normal operating limit conditions, the effect of carbon fiber on the improvement of structural stiffness is less than 10%, or no improvement at all.

The scope of application of carbon fiber bending strengthening

When the concrete structure is reinforced by carbon fiber wrap due to its poor flexural bearing capacity, the damage shape of the reinforced structure depends on the strengthening of the original structure on the one hand, and on the other hand the amount of carbon fiber. Now assuming that the original structure is a suitable strengthening member, the damage shape of the strengthening structure can be divided into the following three conditions.

⑴The amount of carbon fiber is less. When damaged, the marginal concrete in the compression zone is crushed, the tensile steel bars yield, and the carbon fiber can reach a higher tensile strain.

⑵The amount of carbon fiber is moderate. When damaged, the marginal concrete in the compression zone is crushed, the tensile steel bar yields, and the carbon fiber can reach a certain medium tensile strain.

⑶ More carbon fiber consumption. When damaged, the marginal concrete in the compression zone is crushed, the tension steel bar yields, and the carbon fiber strain is very low.

Among the above three situations, the third situation is not suitable because of the large amount of carbon fiber and the low strength utilization rate. The first strengthening method is suitable for beams with a larger section height, and the second strengthening method is suitable for slabs or flat beams with a smaller section height.

This is mainly because for plates or flat beams, when the carbon fiber does not reach a high tensile strain, the structure can be damaged due to excessive deformation. The detailed limit depends on the ultimate tensile strain and loading method of the carbon fiber.

Anti-torsion question

For the torsion-resistant strengthening of concrete structures with carbon fiber materials, few studies have been conducted at home and abroad. From the perspective of the torsion damage mechanism of the concrete structure, whether the fiber direction of the carbon fiber is perpendicular to the axis or parallel to the axis, it can restrain the development of oblique cracks and play a certain role in strengthening.

However, because when carbon fiber is used for strengthening, on the one hand, cracks in the component are now formed, and the spread of the cracks is now determined. On the other hand, because the ultimate strain of carbon fiber can be as high as 10000με, and ordinary steel has a strain of less than 2000με. If the strain is increased to more than 4000με, the width of the concrete cracks has already expanded greatly, and it must begin to develop to other surfaces, and the structure is close to damage. At this moment, the stress that the carbon fiber can reach is still very low, so the role of carbon fiber wrap in strengthening the torsion member needs to be further studied and determined.

Carbon fiber strengthening effect:

We choose carbon fiber wrap to reinforce schools, shopping malls, homes, etc., to ensure the safety of life and property. Therefore, the first requirement for choosing carbon fiber wraps is: safety.

Is carbon fiber strengthening safe? Is it unreliable? Can the strengthening effect be achieved? What are the standards? How to identify?

In the "Technical Specification for Safety Appraisal of Engineering Structure strengthening Materials" (GB 50728-2011), the following provisions are made for the inspection items and qualification indicators for the safety appraisal of carbon fiber composite materials:

According to the requirements of national standards for carbon fiber wraps, Dr. strengthening sent the carbon fiber strengthening materials produced by himself to an authoritative testing organization for testing. The results are as follows:

We can see from the report that the safety assessment of carbon fiber wraps mainly includes tensile strength, elastic modulus, elongation, bending strength, interlayer shear strength, the positive tensile bond strength with the substrate, and the mass per unit area are carried out.

How long is the life of the carbon fiber wrap reinforced house? :

To talk about the life of carbon fiber strengthening, we must first look at the factors that affect the durability of carbon fiber wrap. The editor believes that there are the following points:=

1. The quality difference of carbon fiber yarn.

Relevant regulations clearly state that the fibers used for carbon fiber composite materials must be continuous fibers, and the carbon fibers used as the strengthening of the load-bearing structure must be polyacrylonitrile-based (PAN-based) 24K and small bundles of fibers below 24K, and the use of large bundles is strictly prohibited. The quality of carbon fiber yarns from different manufacturers are also different.

2. In addition to the differences in the quality of carbon fiber yarns, the quality of the braided yarns used for weaving carbon fiber wraps is also very different.

At present, there are hot-melt thread, cotton thread, glass fiber, nylon thread, etc., which are fixed and edge-sealed on the market. The high-quality carbon fiber wrap uses hot melt lines.

(The hot melt line is a linear connecting material made of polymer that can be melted by heating. The temperature can reach 150℃ during binding. A good hot melt line can withstand high temperatures of four to five hundred degrees.)

Some unscrupulous merchants use ordinary cotton thread instead of hot melt thread to save costs. There is not much difference in appearance, but they are far different in terms of high temperature resistance and fatigue resistance.

3. The impact of the harshness of the strengthening environment on materials

Relevant institutions have tested the aging resistance of carbon fiber composite materials in a variety of typical environments (water environment, acidic environment, environment with high alkali content). Test The carbon fiber wrap and carbon fiber wrap composite material are immersed in a typical environment for 10d, 20d, 30d, 40d, 50d, 60d, then taken out to dry, and then subjected to a tensile test.

The test results show that without protection, the mechanical properties (elastic modulus, tensile strength, elongation) of carbon fiber wrap are very small after being immersed in water, acid solvent, and alkali solvent for 60 days. This shows that carbon fiber wrap has good durability in these media.

However, for the strengthening of buildings in offshore areas such as ports and wharves, carbon fiber is inevitably subject to physical and chemical erosion of seawater because of long-term exposure to the special environment of seawater immersion. In addition, wind waves, ice impacts, freeze-thaw cycles, etc., also cause a little damage to the carbon fiber wrap.

At the same time, the test showed that the durability of carbon fiber itself to the medium is very good, and the durability of carbon fiber strengthening to the medium mainly depends on the durability of the carbon fiber structural adhesive.

In summary, the durability of carbon fiber wrap is very strong, but it cannot be accurately estimated at present, and there is no clear test data in the industry that can indicate the service life of carbon fiber wrap.

However, the national standard sets the service life of carbon fiber structural adhesive to 50 years. As the main body of carbon fiber strengthening, carbon fiber wrap has a life span of more than 50 years.

The carbon fiber wrap here refers to the high-quality carbon fiber wrap produced by regular manufacturers that meets the national standards. Those inferior carbon fiber wrap not only have a life span of less than 50 years, but also greatly reduce the service life of the building, leaving hidden dangers to the safety of life and property. Therefore, it is very important to choose good carbon fiber series products.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

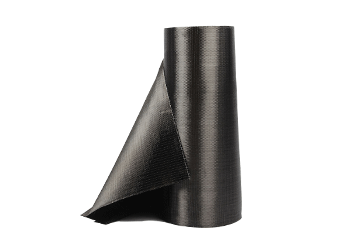

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.