Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

FRP in strengthening of reinforced concrete beam

Traditional strengthening methods for flexural members of reinforced concrete beams include bonding steel strengthening, enlarged section method, and external post-tensioning prestressing method. However, these traditional strengthening methods have some inherent shortcomings. Such as difficult construction and poor durability. Fiber-reinforced plastic (FRP) has the advantages of high strength, light weight, convenient construction, and corrosion resistance. In recent years, it has been widely used in civil engineering, especially the repair and strengthening of old structures.

The technology of FRP strengthening and repair of reinforced concrete structures is to paste the carbon fiber cloth on the surface of the concrete with a supporting adhesive resin to play a role in structural strengthening and seismic strengthening. At present, there are mainly two common process methods used for FRP to strengthen the old structure. One is the wet bonding method, that is, the FRP cloth is not moistened and pasted with resin on site. The other is to prefabricate FRP materials into various profiles, such as pultruded sheets for perimeter and shells made of filaments for column strengthening. Among them, the wet bonding method has wide applicability in on-site construction. Applicable to various types of structures (buildings, structures, bridges, tunnels, chimneys, etc.) various structural shapes (rectangular, circular, curved, etc.), various structural parts (beams, plates, columns, nodes, arches, shells, piers, etc.) are currently the most widely used.

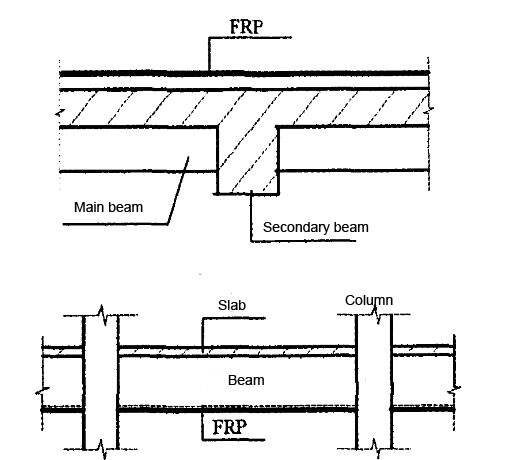

The form of bending strengthening with FRP

The flexural strengthening of beams with FRP cloth is a more widespread use of FRP cloth in strengthening, and its forms are as follows:(1) strengthening for mid-span bending,(2) strengthening of beam support. As shown in Figure 1. That is, paste FRP board or FRP cloth on the bottom of the beam.

Form of shear strengthening with FRP

In the shear strengthening of beams, there are many ways to paste FRP. Including just sticking FRP on both sides of the beam, sticking FRP on the side of the beam and the U-shaped tensile surface, and wrapping FRP along the entire beam section. Either FRP strips can be used for interstitial pasting, or fiber cloth can be used for continuous full pasting. Because the FRP material has strength only along the fiber direction, the fibers can be arranged in the direction that is most conducive to controlling shear cracks. The failure modes of FRP shear-strengthened beams in the experiment mainly include the shear failure of FRP tensile fracture, the shear failure of FRP untensioned fracture, the shear failure caused by FRP peeling and local failure.

(1) Shear failure of FRP tensile fracture This failure mode is usually caused by a shearing diagonal crack. First, vertical bending cracks are formed from the tension surface of the beam. One of the cracks near the support may develop toward the loading point and form an oblique crack. Sometimes diagonal cracks may appear suddenly. As the width of the diagonal crack increases, the maximum strain in the FRP reaches the ultimate strain, which leads to local fracture of the FRP. Then the fracture failure of FRP develops along the direction of the diagonal crack, which eventually leads to brittle failure of the beam.

(2) Shear failure of FRP without breaking. Except that FRP did not break when the beam is broken, the process of this failure mode is basically the same as that of FRP breaking.

FRP strengthening construction notes

The strengthening of concrete components with FRP cloth depends on the efficiency of the adhesion of FRP cloth to the surface of the component. Therefore, the strengthening effect is not only related to the properties of the FRP cloth material and the number of layers attached, but the construction quality also has a great influence on the strengthening effect.

Sum up of FRP strengthening

FRP has the characteristics of high strength, light weight, and convenient construction. It is being widely used in the repair and strengthening of old structures. The effect of FRP cloth strengthening and its possible damage form are greatly affected by the construction quality. Therefore, the construction quality must be strictly controlled during the construction to ensure that the FRP and the structure are fully bonded. In addition, proper anchoring measures should be taken at the fracture of FRP, so as to take advantage of the high tensile strength of FRP.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.