Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

To the design of structural steel plate bonding adhesive use fixed number of year for 50 years, should pass the wet and heating ageing resistance and long-term stress resistance ability test.

Temperature condition of structural steel plate bonding

1 the temperature should be at 50 C (+2, -1) C;

2 relative humidity should be maintained at 95%~100%.

3 the constant temperature and humidity time should be 60d or 90d from the temperature and humidity in the box.

Control of heating, constant temperature and cooling process

Heating system

Within 1.5h~2h, the temperature in the aging chamber should be continuously and evenly raised from 25 (+3, -1) (+3, -1)) to 50 (+3,-1). The relative humidity should also be increased to more than 95%. In this process, the surface of the sample should be condensed water.

Constant temperature and constant humidity system

The temperature and humidity in the effective working area of the aging box should be uniform without obvious fluctuation, and real-time monitoring should be carried out according to the indication value of the sensor.

Cooling system

Cooling should begin immediately after 90 days of continuous constant temperature, and should be continuously and evenly reduced from 50 C to 25 2 C within 1.5 h ~ 2 h, but the relative humidity should remain above 95%.

Detection step

When the specimens are completely cured, the initial shear strength of the specimens in the control group should be determined immediately according to the current national standard "Determination of Tensile Shear Strength of Adhesives (Rigid Material to Rigid Material)" GB / T7124 or appendix R of this specification.

The aging test group specimens are put into the aging box, and the specimens are not allowed to contact each other, the specimens and the wall of the box. For arbitration tests, the distance between the sample and the box wall, the bottom of the box and the top of the box shall not be less than 150mm.

The temperature and humidity control of the aging test shall be carried out according to the requirements and requirements of the experimental conditions.

In the process of testing, if the sample is to be taken out or put in, the time of opening the door should be short to prevent the surface of the sample from droplets of condensation.

When constant temperature and humidity reach 28d, a group of specimens should be removed for shear test. If the shear strength of the specimen decreases by more than 15%, the aging test should be suspended and directly judged to be unqualified; the test should not be continued to avoid misjudgment. If the percentage of shear strength reduction is less than 15%, it should continue to the prescribed time.

After 90 days (60 days for Grade B glue), the specimen can be taken out and placed in a sealed vessel when the temperature is lowered to 35 C. After balancing with room temperature, the shear failure tests are carried out one by one, and each group of tests should be completed within 30 minutes.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

two-components modified epoxy resin adhesive, with high quality plastic tube, double cartridge package

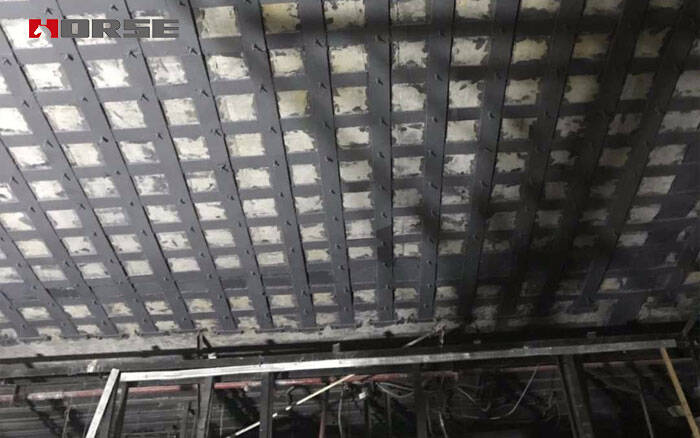

Two-component epoxy modified epoxy structural strengthening adhesive for bonded steel plate to concrete

Modified epoxy resin structural perfusion adhesive, specifically for supporting adhesive bonded steel reinforcement