Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Horse Construction will reveal the advantages of high quality unidirectional carbon fiber cloth from the aspects of raw materials, knitting technology, glue adaptability and so on.

Credit is not only a moral norm, but also the cornerstone of the survival and development of enterprises. Hummer has been adhering to the value of honesty, customer first. We put our customers first and try our best to solve all the problems for you.

Since its establishment in 2006 to 18 years, the company has been continuously investing in R&D products for 13 years, improving product system and improving product quality. Major initiatives are taken every year. In 2010, sales of reinforcement materials exceeded 50 million yuan. In 2015, sales exceeded 70 million yuan, ranking first. In 2017, sales reached 150 million yuan.

Speaking of product quality, what kind of carbon fiber cloth can be regarded as high quality?

Reinforcement materials should not only have good mechanical properties, all aspects of performance up to standard, but also be well constructed when used by workers.

Next, Horse Construction will reveal the advantages of high quality carbon cloth from the aspects of raw materials, knitting technology, glue adaptability and so on.

As we all know, carbon cloth has the advantages of high strength, high modulus, light weight and so on. However, the performance of carbon cloth produced by different manufacturers varies greatly. I wonder if you have ever encountered the phenomenon that carbon cloth has wool and joints. Carbon cloth if there are wool and joints not only affect the strength of carbon cloth performance, workers in the construction also prone to allergies. Actually, the main reason why carbon cloth has wool and joints is that the raw materials used are not good. If the carbon filament itself has wool, but the length is not long enough, the woven carbon cloth will certainly have wool, and inevitably there will be joints.

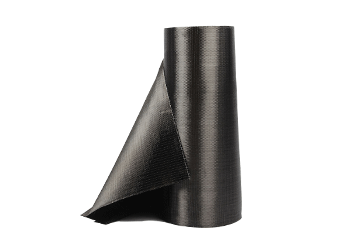

Horse Construction uses imported 12K small tow carbon filaments with a single filament strength of 5400 MPa. 12K small filament makes the glue better soaking, less dispersity and stable tensile performance. Our single filament length is 5000 meters, and the finished carbon cloth is 100 meters per roll, so we guarantee that no joint will appear in each roll of carbon cloth. The wool and joints were eliminated from the source. The strength performance of the product is guaranteed.

High quality carbon cloth depends on good raw materials and weaving technology. We have improved every link that will affect the strength of carbon cloth. Think about the raw material is a good raw material, but in the process of transporting carbon filament, if there is damage to carbon filament, wool will appear. In view of this situation, Hummer independently developed a yarn rack, so that the carbon filament in the process of transporting no damage, to ensure the integrity of carbon filament.

When the tension of each carbon filament is different during weaving, the force of each carbon filament is not uniform, resulting in uneven finished products and uneven carbon cloth itself, so it is very difficult to smooth when pasting. The tension constant system independently developed by our company makes the tension of each carbon filament the same, the force uniform, and exerts the strength of each filament.

The traditional knitting machine is impact weft insertion, easy to wear carbon filament, weft missing and weft breaking, resulting in carbon cloth belly wavy, we use the German Donier loom, point-to-point active weft insertion, weft threading after the warp is closed, will not wear carbon filament, and weft missing and weft breaking, while solving the problem of big belly and wavy. The whole process of intelligent computer control, there will be no shortage of two. And our machines can weave special specifications of carbon cloth.

Adhesive for carbon cloth should be reported for suitability. The polarity of the surface of carbon cloth is different. If it is not suitable for glue, the wettability will be greatly reduced. It will not infiltrate into the interior of carbon filament, which will affect the bonding effect, lead to the strength not up to the standard and affect the safety of the whole project. We produce carbon cloth, also produce carbon glue, and develop suitable glue, so the adaptability and wettability of our glue are very good.

The finished carbon cloth is even and smooth, moderate in hardness and softness, and easy to stick. At the same time, it solves six common problems of carbon cloth.

All of the above I have said is certified by an authoritative inspection report. This is a random sample of the inspection report of the State Inspection Center in the base of 30,000 square meters. It shows that all of our shipments are guaranteed. If there is spot check on the construction site, there is no need to worry about it at all.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.