Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

concrete power plant strengthening

Abstract: With the continuous progress and development of economic construction, the pace of development of the power industry is getting faster and faster, and the power plant has put forward higher requirements for the quality of related construction projects.

The building will be affected by human factors and the natural environment during long-term use, and its function will be weakened.

The physical properties of each type of concrete building materials are different. Even for concrete building materials of the same nature, due to different reinforcement designs, their technical updates and renovations will be different.

Therefore, it is necessary to strengthen the reinforcement design of the concrete structure of the main power plant to build a solid foundation for the construction of power engineering. Through the analysis and discussion of the reinforcement design of the concrete structure of the main power house of the power plant, it is hoped that it will play a reference role in the development of power engineering buildings.

1 Reinforcement design method of concrete structure

1.1 Direct reinforcement method

1) Enlarged section reinforcement method. The greater the area and strength of the reinforced concrete cross-section, the higher the bearing strength. In the case where the reinforcement ratio of the original section is not high, to increase its bending resistance, the area of the main reinforcement section can be increased. Add a cast-in-place concrete layer in the tension zone of the cross section to make the newly added part work with the original member to achieve the effect of mentioning the bearing capacity of the member. The enlarged section reinforcement method is relatively simple to operate and is a common reinforcement method. Therefore, the construction experience of technicians is generally more mature, and it is more commonly used in concrete reinforcement of general structures such as walls, beams, columns, and slabs.

2) Replacement concrete reinforcement method. This reinforcement method has similar features to the enlarged section reinforcement method, and the reinforcement will not affect the headroom of the building. When the strength of the concrete in the compression zone is low, or the concrete load-bearing members such as beams and columns have serious defects, the method of replacing concrete can play a good role in strengthening.

3) Bonding steel reinforcement method. The reinforcement method imposes higher requirements on the operation level of technicians and the adhesive process, and is generally used to reinforce the tensile or bending members under static conditions and under normal humidity. In areas where the bearing capacity of the members is weak, sticking steel plates on the surface of the reinforced concrete bending members can strengthen the bearing strength of the reinforced members. This method is relatively simple and fast to implement. There is no wet operation or only a small amount of wet operation on site, which will not affect people's production and life. After operation, it will not damage the appearance of the original structure or affect the original headroom.

4) Paste fiber reinforced polymer(FRP) reinforcement method. In this method, cementitious materials are used to stick fiber-reinforced composite materials in the tensile region of the reinforced member to make it interact with the reinforced section, thereby enhancing the bearing capacity of the member. There are similarities with the advantages of the bonded steel reinforcement method. It also has the advantages of moisture resistance, corrosion resistance, and low maintenance costs. However, special fire protection treatment is required, and it can be used for general buildings or concrete structural members with mechanical properties.

1.2 Indirect reinforcement method

1) Prestressed horizontal tie rod reinforcement method. Under the combined force of the prestress and the newly added external load, the concrete flexural member strengthened by this technology will form an axial tension in the tension bar. The anchoring of the rod end of the tie rod is transferred eccentrically to the component, forming an eccentric compression effect in the component. This force exerts a restraining effect on the bending moment generated by some external loads, thereby promoting the bending resistance of the component to a certain extent. Under the influence of the horizontal lifter, the cross-sectional stress characteristics of the original member changed from bending to eccentric compression. Therefore, the bearing capacity of the original member under compression and bending determines the bearing capacity of the reinforced member.

2) Reinforcement method of prestressed lower brace. When strengthening the concrete structure of the main power plant, after using this method, the reinforced concrete members will form a composite statically indeterminate structural system. This system is formed by the combination of the lower brace and the reinforced member. The combined force of the prestress and the external load causes the axial force in the tie rod to be transmitted from the connection point of the member to the reinforced member, which plays a certain role in suppressing part of the external load and the bearing strength of the member has also been improved. This reinforcement method not only has a good effect, but also can greatly increase the bearing strength of the concrete structure. However, this reinforcement method is greatly affected by the ambient temperature. When the temperature is higher than 60 degrees, it cannot be used without adequate protection for the construction personnel.

3) Add support reinforcement method. This reinforcement method is suitable for the reinforcement of concrete structures where conditions permit. Through a certain technology to reduce the span of the bending member, the pressure on the reinforced member is reduced, thereby improving the bearing capacity of the structure. This reinforcement method is simple and effective in actual operation, but it is easy to cause certain damage to the original appearance of the building during the operation, the function of the structure is also affected to a certain extent, and the use space of the main power plant is also reduced .

2 Common technologies supporting the reinforcement and reconstruction of concrete structures

Common supporting technologies include planting reinforcement technology, underpinning technology, column removal, and crack repairing technology. The main power plant can be said to be the central system of the power enterprise, and the safety of its buildings must be guaranteed. The construction personnel should strengthen the study, study and use of related technologies.

3 Conclusion

All in all, the development of the power industry has played an increasingly important role in people's production and life. The construction of the main power plant is an important part of power engineering construction. As the technical update and transformation of the main power plant and the requirements for seismic fortification of buildings become higher and higher, the reinforcement design and treatment of the concrete structure of the main power plant should be strengthened during the construction process.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

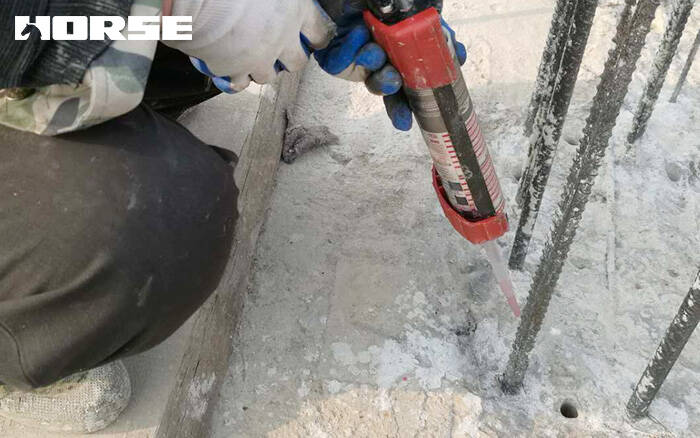

two-components modified epoxy resin adhesive, with high quality plastic tube, double cartridge package

Modified epoxy resin structural perfusion adhesive, specifically for supporting adhesive bonded steel reinforcement

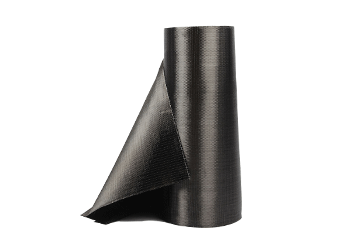

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.