Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

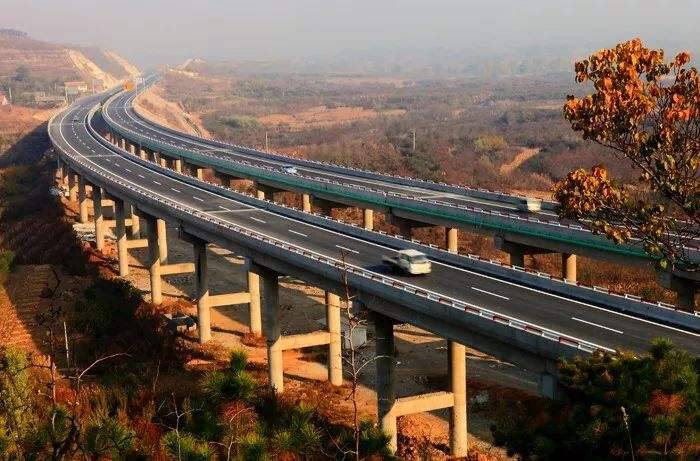

Unidirectional carbon fiber for high-speed bridge reinforcement

Overview of Tanggang Highway Bridge Reinforcement Project

Tanggang Expressway K4+863.7 small bridge, with a span of 1-13 m. The upper structure is a prefabricated reinforced concrete hollow slab, and the lower structure is a thin-walled pile foundation. The right cross angle is 80 degrees, double bridge, half bridge width is 14.5 m, the width of the separation belt between the two bridges is 1 m, and the bridge deck is 9 cm asphalt concrete + 10 cm cement concrete. The design load of the bridge is automobile-super 20 and trailer-120. The diseases of the upper beam slab are: most of the slab bottom spans and 1/4 of the network cracks and water seepage phenomenon, the maximum crack width is 0.4 mm.

Construction technology of bonding unidirectional carbon fiber

General requirements for bonding unidirectional carbon fiber fabric

(1) The reinforcement and repair of concrete structures by bonding unidirectional carbon fiber fabric should be completed by a professional construction team familiar with the construction process, and carefully organized and carefully constructed.

(2) Before the surface treatment and the unidirectional carbon fiber board are pasted, the line should be positioned according to the reinforced design position.

Material requirements

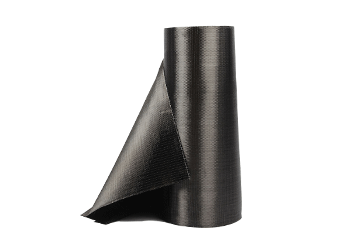

(1) The main performance indicators of unidirectional carbon fiber fabric should meet: the minimum tensile strength is greater than 3 000 MPa; the modulus of elasticity is greater than 2.0 x 105 MPa; the elongation is greater than 1.7%.

(2) The positive tensile bond strength of the underlying resin is not less than 2.5 MPa and greater than 1.2 times the tensile strength of the reinforced concrete.

(3) The positive tensile bond strength of the leveling material is not less than 2.5 MPa, and is greater than 1.2 times the tensile strength of the reinforced concrete.

(4) The performance indexes of impregnating resin and bonding resin should meet the following requirements: tensile shear strength not less than 10 MPa, tensile strength not less than 30 MPa, and bending strength not less than 40 MPa. The positive tensile bonding strength is not less than 2.5 MPa, and greater than 1.2 times the tensile strength of the reinforced concrete.

(5) The surface protection material should have reliable bonding strength and good deformation performance with the impregnating resin.

Reinforcement material characteristics and applicable conditions

unidirectional carbon fiber fabric can be used for various forms of reinforcement such as bending resistance, shear resistance, compression resistance (eccentric compression) and seismic resistance. This method is suitable for bending and shear reinforcement of concrete beam bridges and slab bridges. For old bridges with low reinforcement ratio or severe steel corrosion, the reinforcement effect is particularly significant. It is also suitable for shear resistance, compression reinforcement of concrete piers, seismic ductility reinforcement, and repair after earthquake damage.

Unidirectional carbon fiber fabric reinforcement has the following advantages

(1) High strength, tensile strength is about 10-15 times that of ordinary steel.

(2) After reinforcement, the corrosion resistance and durability of the structure can be greatly improved.

(3) Light weight, the unidirectional carbon fabric of this project is about 300 g/min, basically does not increase the weight of the structure and the section size; it is flexible, easy to cut, and has a wide range of applications.

4) The construction is simple, does not require large construction machinery and turnover materials, is easy to operate, and is economical;

(5) The construction period is short, and the project example only takes 7 days.

Unidirectional carbon fiber sheet reinforcement construction steps

(1)Substrate surface treatment

(2)Apply primer

(3)Paste unidirectional carbon fiber fabric

(4)Surface protection

(5)Inspection and acceptance

Summary of experience

(1) A total of 7 prefabricated slabs of the whole bridge of this project are reinforced with unidirectional carbon fabric, and it takes 7 days to stick the unidirectional carbon fabric. Practice has proved that the construction process of bonding unidirectional carbon fabric is simple, and it can be operated with small electric tools. It has fewer types of work, less labor, short construction period, and fast progress. It greatly shortens the time of construction and has great economic and social benefits.

(2) This bridge is a cross-road bridge. Steel pipe supports are used when bonding unidirectional carbon fabric. Therefore, safety work for driving and pedestrians should be done during construction to ensure construction safety and quality.

(3) unidirectional carbon fabric is prone to lint and hairiness during use. If it adheres to the skin, it will cause irritation and strong itching. Inhaling people will cause throat, trachea, and lung injuries, so it is best to wear work fabrices, gloves, masks, goggles, etc. during construction. After the construction is completed, clean the leaking parts with soapy water.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

Modified epoxy resin structural perfusion adhesive, specifically for supporting adhesive bonded steel reinforcement

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.