Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

the use of unidirectional carbon fiber sheet in structural reinforcement of industrial plant

1 Overview of structural reinforcement projects

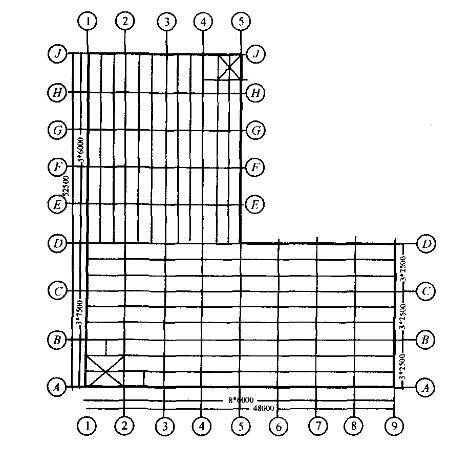

A five-story industrial factory building is located in Miyi County, Panzhihua City, with a total construction area of about 9,000 m2. The main body adopts a cast-in-place reinforced concrete frame structure. The plane is shown in Figure 1. The foundation is an independent foundation under the column, and the supporting layer is a strongly weathered rock layer. The project was built in 1990. Due to construction quality problems and long-term overloaded use of the structure, many walls, beams and floors have been cracked and the surface plaster layer has fallen off locally.

2 Structural inspection and analysis

The main contents of the project site inspection and appraisal include:

(l) Physical performance testing of component materials closely related to structural safety, such as concrete strength, steel bar distribution, etc.;

(2) Recheck the cross-sectional dimensions of existing components, such as grid size, main load-bearing component cross-section and floor thickness, etc.;

(3) Structural durability testing, such as the depth of carbonization of component concrete and the corrosion of steel bars.

The test results of the structural measures show that the configuration of beams, columns and waist reinforcement, the tie between the columns and the retaining wall, and the setting of door and window lintels in this project all meet the requirements of the current design specifications. The test results of the concrete carbonation depth show that the concrete carbonation depth of the components of this project is relatively large, most of which are above 30 mm, which exceeds the thickness of the concrete protective layer (greater than or equal to 25 mm). The steel bar loses its alkaline protection and affects the durability of structural members.

3 Structural reinforcement treatment plan

Through the comparison of several schemes, for example: the enlarged section reinforcement method, the reinforcement of the column with the planted reinforcement and the reinforcement of carbon fiber composite materials. Due to the short construction period required by the owner, the workshop should be put into use as soon as possible after reinforcement. At the same time, the comprehensive cost comparison of several schemes and various factors considered that the use of unidirectional carbon fiber sheet materials to strengthen the columns and beams is the best.

1) Reinforcement design principle

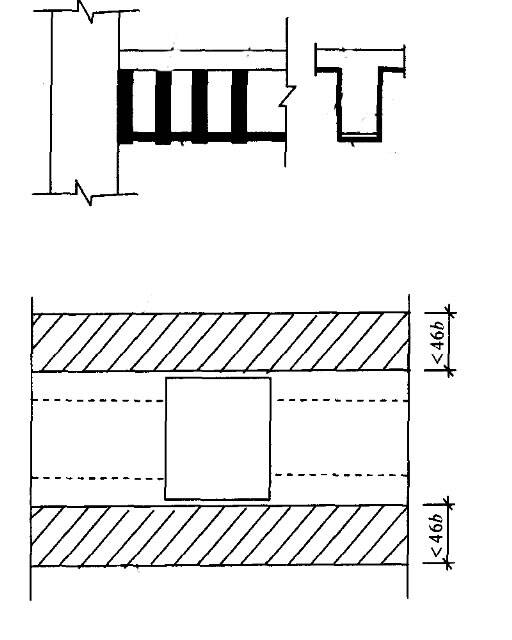

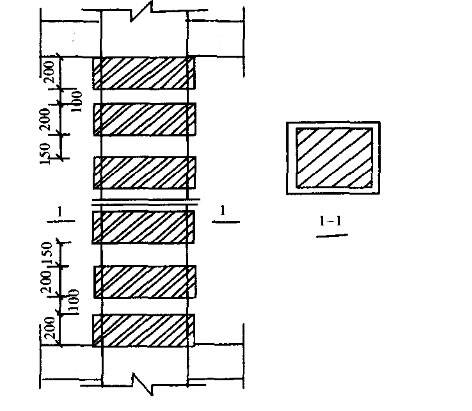

When the positive and negative bending moment areas of reinforced concrete flexural members are reinforced (the positive and negative moments in the beam are insufficient), the tensile surface is pasted with carbon fiber sheets in the axial direction. And should be extended to the edge of the support, and should be set at the end of the fiber sheet, including the cutoff and the two sides of the concentrated load point, U-shaped chicks or horizontal bead.

For reinforced concrete columns, use carbon fiber sheets along the axis of the column to strengthen the normal section bearing capacity of large eccentric compression members, and add mechanical stabilization measures at both ends of the column.

2) The reinforcement construction of the plant is carried out according to the following procedures.

(1) Before construction, it is necessary to locate and stake out according to the construction drawing, and fix the reinforcement position on the spot;

(2) Surface treatment of the base layer: smooth the surface, remove all impurities on the surface, remove the 2-3 mm cement mortar layer on the surface, until the hard aggregate is exposed, after polishing, use a powerful blower or duster to remove the surface dust;

(3) The preparation of the binder must be carried out in strict accordance with the instructions for use and the relevant experimental mixing ratio, stirring at low speed, and mixing fully;

(4) Pasting and curing of carbon fiber sheets: Apply a uniformly mixed adhesive (generally epoxy resin) to the surface of the concrete base layer at the fixed reinforcement position. The paste is required to be flat and compact, without hollow bubbles. When performing multi-layer pasting, the second layer can be pasted only after the lower finger touches dry. For the pasted carbon fiber sheet, it is strictly forbidden to disturb within 24 hours. After the adhesive is hardened (after 48 hours), decorative plastering can be carried out on the surface of the structure to organize the subsequent process construction;

(5) Reinforcement acceptance: The bonding quality between the carbon fiber sheet and the concrete can be judged by lightly tapping with a small hammer or pressing the surface of the carbon fiber sheet by hand. The total bonding area shall not be less than 95% of the reinforced area. When the area of the hollow drum is less than 100 cm2, it can be remedied by syringe injection. When the area of the hollow drum is greater than 100 cm2, the carbon fiber sheet at the hollow drum should be cut off, and a carbon fiber sheet of equal thickness should be reattached.

4 Project summary

It has been more than a year since the acceptance of the carbon fiber reinforcement construction of the plant, and the current condition is good, and the original structure has no cracks or other undesirable phenomena.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

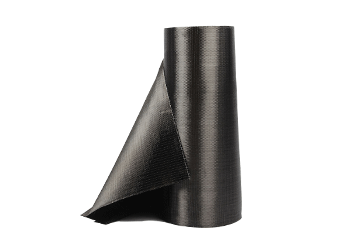

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.