Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Unidirectional carbon fiber sheet

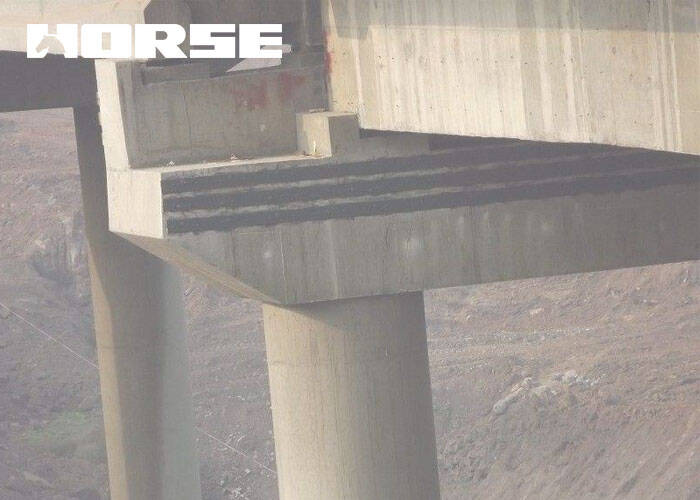

Principle of strengthening bridge structure with unidirectional carbon fiber sheet

The existing reinforcement techniques and methods for the superstructure of the old bridge are mainly the enlarged section reinforcement method, the outer steel method, the sprayed concrete method, the additional support point reinforcement method, the bonded steel reinforcement method, the prestressed reinforcement technology or the method of changing the transverse distribution coefficient of the bridge, etc. . These methods have their own advantages and strengths, but most of the construction is complicated, and there are some shortcomings.

Externally bonded carbon fiber reinforced plastic sheet (CFRP) is a reinforcement technology developed abroad in the past 20 years. The principle is similar to that of steel plate reinforcement, which is to paste tensile materials on the tensile side of the structure to share the force with the structure and strengthen the reinforcement. Carbon fiber reinforced plastic, also known as Carbon~Fiber Reinforcement Polymer (CFRP), is an advanced composite material composed of carbon fiber and matrix resin. The carbon fiber is a fibrous carbon material with a carbon content of more than 90% in its chemical composition. In order to improve the affinity between the carbon fiber and the matrix, the fiber itself needs to be surface treated to form an active group that can react with the matrix. Because the element of carbon cannot be melted at high temperature (sublimation at 3800K), it is insoluble in various solvents. Therefore, it has not been possible to make carbon fiber with the simple substance of carbon so far. Carbon fibers can be prepared by solid-phase carbonization of high molecular weight organic fibers or gas phase pyrolysis of low molecular weight hydrocarbons. At present, carbon fibers are mainly made of polyacrylonitrile (PAN) or mesophase pitch (MPP) fibers through high-temperature carbonization, and are characterized by extremely high tensile strength and good corrosion resistance. The carbonized fiber is monofilament, and the diameter is usually between 5um~8um. It is composed of a large number of carbon fiber monofilaments to form carbon fiber materials for engineering.

The matrix resin includes unsaturated polyester resin, epoxy resin and vinyl ester resin, etc., which can be cross-linked and cured under the action of a curing agent, so that the fiber material and the resin are bonded together, showing the superior performance of the composite material. At present, the matrix resin used with carbon fiber is mainly epoxy resin, because the first consideration for carbon fiber reinforced plastics for civil engineering reinforcement is the strength of the resin and the safety and health of the construction personnel and the construction environment itself. Because epoxy resin has the advantages of high strength, good elongation, low irritation and no volatile solvents, it has become the mainstream of the matrix material in the carbon fiber reinforced plastic reinforcement structure. Modified epoxy resin, its function is to connect the dispersed carbon fiber monofilament, make it bear the force together, and exert the overall strength.

Features of unidirectional carbon fiber sheet for beam reinforcement

1) Excellent corrosion and weather resistance

The most direct reason why carbon fiber reinforced plastic is used as a substitute for steel in the field of civil engineering is that it has corrosion resistance and weather resistance that steel can't match. Corrosion of steel bars in bridge structures is one of the most serious diseases of bridges. According to the report of the US Highway Strategy Research Project, the cost of repairing bridge damage caused by rust in the United States in 1986 reached 20 billion US dollars, and this cost is still increasing at a rate of about 500 million US dollars per year. Rebar corrosion is generally electrochemical corrosion. When the chloride ion intrusion, the alkalinity of the concrete environment, or the tensile cracking and other factors cause the complete or partial destruction of the passivation state of the steel bar surface, a large potential difference appears in different parts of the steel bar surface, forming an anode and a cathode. Under certain circumstances (such as the presence of oxygen and water), the steel bars will corrode, reducing the bearing capacity of the structure. According to the research results, in a weak acid environment, after 10,000 freeze-thaw cycles, alternating dry and wet, certain light time, and immersion in 70°C hot water for 30 days, the durability, corrosion resistance and aging resistance of carbon fiber The performance is not reduced, and the fatigue strength still retains 80%. The matrix epoxy resin used with carbon fiber has good stability in the range of pH 3~l3 under normal use temperature. In addition, when accelerated aging is 10000h (approximately equivalent to more than 35 years of actual exposure in the atmosphere), The adhesive strength of the matching matrix resin remains unchanged and has good durability. It can be seen that carbon fiber reinforced plastic has excellent corrosion resistance, and therefore, in a short period of time has become the most competitive substitute for steel.

2) Simple process, convenient construction, high work efficiency

The carbon fiber sheet reinforced bridge structure has no wet work, no large construction equipment, no on-site fixed facilities, and less construction space. Commonly used carbon fibers are cloth materials and plates. The cloth material is a one-way or two-way cloth fabric. Its width can be 20cm, 30cm, 50cm, 100cm, and the length is 50m/tire~100m/roll. On-site use can be cut with scissors or blades as needed. Unlike steel plates, special cutting tools are not required. According to relevant statistics, the same is the paste reinforcement method, and the paste carbon fiber cloth method is 4 to 8 times the efficiency of the paste steel construction.

3) Existing defects

(1) Insufficient ductility; (2) The ratio of elastic modulus to strength is too low; (3) The shear force transmitted by the epoxy resin layer is limited.

The above-mentioned defects limit the application of carbon fiber reinforced plastics in the reinforcement field to a certain extent. Because the structure often requires not only strength reinforcement, but also rigidity reinforcement, and the material properties of carbon fiber determine the rigidity reinforcement that can not be carried out by ordinary technology with better economic benefits. Even if a large amount of carbon fiber reinforced plastic is pasted to improve the structural rigidity, due to the material properties of the epoxy resin and the stress concentration at the bending and shear cracks, it is easy to cause the interface between the carbon fiber reinforced plastic and the concrete to peel off and damage the bond. Ultimately reduce the reliability of the reinforced structure. In addition, due to the high strength of carbon fiber, the existing carbon fiber reinforcement technology cannot fully exert its strength, which also restricts the further application and development of carbon fiber reinforced plastics in the reinforcement field.

Conclusion

Unidirectional carbon fiber sheet reinforcement is a new type of reinforcement technology that has superior performance that other reinforcement technologies cannot match, and has broad application prospects in the field of bridge reinforcement. Although there are certain shortcomings, it is still very suitable for bridge structure reinforcement as long as it is used reasonably and avoids weaknesses. The application of unidirectional carbon fiber sheet reinforcement technology in bridge reinforcement projects can greatly promote the construction of transportation infrastructure.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.