Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Carbon fibre reinforcement

Carbon fibre is a new type of material originally used in aerospace engineering. It was used in the reinforcement of bridges and tunnels in the late 1980s. It is a reinforcement material with excellent mechanical properties. Carbon fibre has the characteristics of high strength, convenient construction, light weight, corrosion resistance, etc., and its thermal expansion coefficient is much smaller than that of concrete and steel. Related studies have found that when the temperature rises by 15°C, although the tensile stress is 32.25 MPa, the amount of deformation is small. In the process of highway bridge maintenance and reinforcement, especially ordinary beam bridges with restricted main girder height, carbon fibre reinforcement technology is used for reinforcement, which can improve the bearing capacity of the bridge. At the same time, the construction process and the construction process are simple, the chemical stability is good, the corrosion resistance does not increase the dead load of the bridge and the size of the structural section. It is a relatively economical, reasonable and fast reinforcement method. At present, carbon fibre sheets have been used to reinforce various bridge structures on a large scale in China. Follow-up observations have proved that the reinforcement effect is good and the development prospects are broad.

How carbon fibre reinforced bridges work

Due to the material properties of carbon fibre, when the bridge structure is deformed, it will not immediately participate in the work. It will gradually take effect when critical cracks appear in the reinforced part and the cracks continue to increase. In the process of using carbon fibre to strengthen the bridge structure, the carbon fibre bundles are first arranged in a unidirectional bundle. Then it is impregnated with epoxy resin to make carbon fibre cloth. Then clean the tension surface of the structure to be reinforced, and paste it with special epoxy resin glue. After the epoxy resin is solidified, it forms a solid whole with the original structure, and bears the force together with the steel bars. To some extent, it reduces the tensile stress on the steel bars, inhibits the development of cracks, and improves the bearing capacity of the bridge structure.

Construction process and precautions of carbon fibre reinforced bridge

When reinforcing the main beam with carbon fibre cloth, the impurities on the surface of the concrete must be thoroughly cleaned up, the honeycomb pitted surface is filled, and the bottom epoxy resin glue is applied. Then level with epoxy putty, brush a layer of epoxy resin adhesive, paste carbon fibre cloth, after completion, perform health maintenance and apply anticorrosive paint.

In the process of carbon fibre cloth pasting and reinforcement, the concrete surface should be treated well. Use epoxy mortar to plug and repair damaged parts, leaking ribs and larger cracks. After completion, use a wire brush to clean up the oil, dust and other debris on the concrete surface to avoid problems such as hollowing and falling after sticking the carbon fibre cloth. In the process of configuring the epoxy resin bonding glue, usually the bottom epoxy resin glue is configured with a curing agent: epoxy resin=2:1 ratio, which can ensure that its viscosity is low and can penetrate into the interior of the concrete, while bonding carbon fibre The epoxy resin glue configuration ratio of the cloth is 2:1. When applying epoxy glue, apply it evenly in the same direction and wait until the surface of the glue is dry before proceeding. In the process of pasting the carbon fibre cloth, it must be evenly pasted and evenly squeezed in the same direction with a banana roller to eliminate air bubbles, and fully soak the carbon fibre cloth to ensure the bonding effect. In the post-maintenance process, ensure that the carbon fibre cloth cannot withstand any collision, and spray the cement mortar after the epoxy resin is cured. After the construction is completed, the carbon fibre cloth that meets the quality requirements has no hollowing, falling, etc.

Concluding remarks

Compared with other bridge reinforcement methods such as enlarged section method and external prestressed reinforcement, the method of strengthening reinforced concrete bridges with carbon fibre cloth has simple construction technology and does not affect driving. Moreover, it has the advantages of short construction period, quick results, good reinforcement effect, and no increase in dead load of the bridge structure. It is a new type of bridge strengthening technology.

With the rapid economic and social development, the traffic volume has increased sharply, and the bearing capacity of highway bridges is facing more and more challenges. The technology of reinforcing highway reinforced concrete bridges with carbon fibre will increase the bearing capacity of the bridge structure, extend the service life of the bridge, and improve the traffic quality of the highway network. It can also be repaired in time when the bridge has minor diseases, and the economic and social benefits are obvious. At the same time, the use of bonded carbon fibre cloth to reinforce the bridge can increase the load-bearing capacity of the bridge without increasing the cross section of the beam or reducing the elevation of the bottom of the beam. The shape of the entire bridge body is beautiful and basically remains unchanged.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.

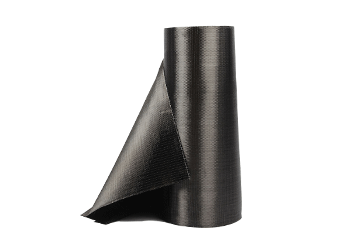

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.